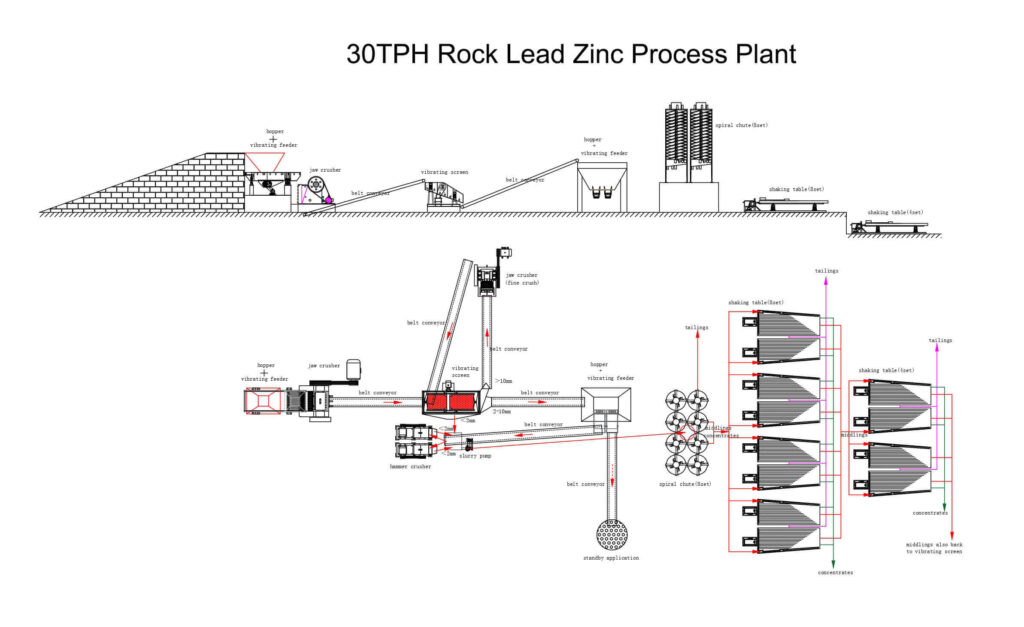

Morocco 30TPH Rock Lead Zinc Process Plant

JXSC has provided a successful 30TPH rock lead zinc process plant in Morocco. We design the gravity process plant process flowchart & plant layout drawing according to ore conditions, provide a complete set of plant machines and send Chinese engineers to the mine site for plant installation & commissioning guidance.

Rock Lead Zinc Process Plant Project Case

Introduction

Minerals: Lead zinc rock oxide ore(6% lead and 5% zinc)

Capacity: 30 TPH

Process: Crushing -> Screening -> Second-stage Crushing -> Gravity Separation

Solutions & Process

Rock Lead Zinc Process Plant

- The vibrating feeder sends the raw materials to the rough jaw crusher for crushing.

- After crushing from the rough jaw crusher, the material is sent to the vibrating screen.

- The vibrating screen divides the particle size of <2mm, 2-10mm, and >10mm.

- Send the <2mm material to the spiral chute. For the material from the vibrating screen, send 2-10mm to the hammer crusher, and >10mm to the fine jaw crusher.

- After the hammer crusher is crushed, send the material to the spiral chute.

- The output of the fine jaw crusher is sent to the before vibrating screen.

- The middlings and concentrates of the spiral chutes go to the first-stage shaking tables.

- The middlings and concentrate of first-stage shaking tables go to the second-stage shaking tables, which can increase the grade of lead and zinc.