Indonesia 100TPH Alluvial Gold Processing Plant

JXSC has provided a successful 100TPH alluvial gold processing plant in Indonesia. We design the ore process plant flowchart & plant layout drawing according to ore conditions and provide a complete set of plant machines.

Alluvial Gold Processing Plant Project Case

Introduction

Minerals: Alluvial Gold

Capacity: 100 TPH

Ore Condition: Contains a lot of slime

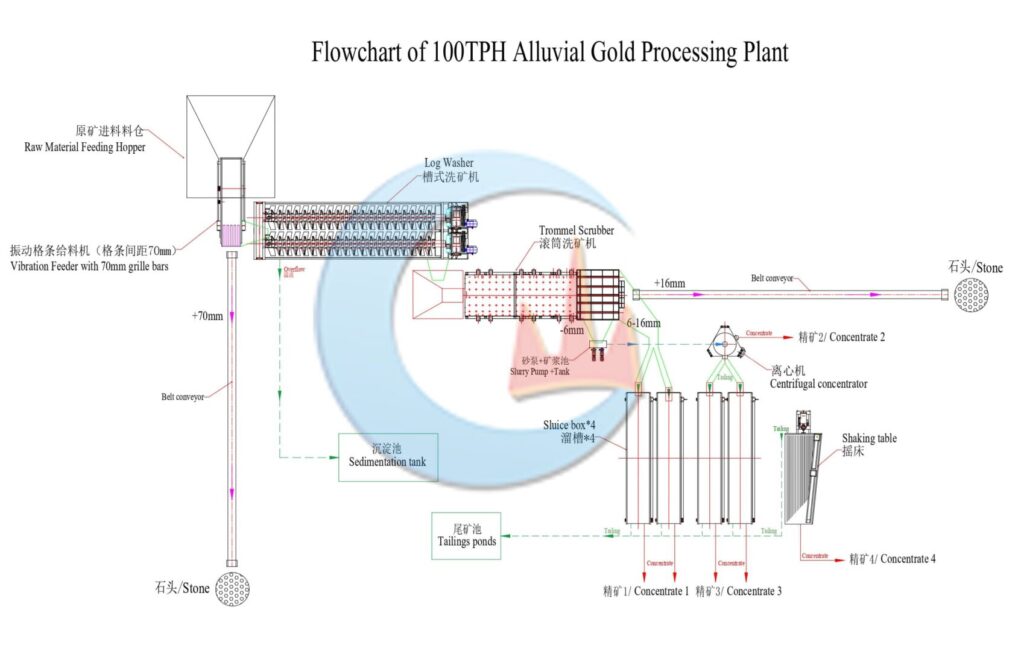

Process: Feeding ->Washing -> Screening -> Gravity Separation

Solutions & Process

Alluvial Gold Washing Plant

Steps of the washing plant

- Use a vibration feeder with a 70mm grizzly bar at first. The -70mm materials will be sent to a log washer to scatter and wash the materials.

- Then after being processed by the log washer. The materials go to the next trommel scrubber to wash the sticky clay. The trommel will have 2 layers of screen, 6mm, and 16mm. So that the 0-6mm materials will be sent to a slurry tank at first, then the slurry pump will send them to centrifugal concentrators to recover concentrated gold. The tailings from the concentrator will be sent to 2 sets of sluice boxes to recover the gold in the tailings.

- The 6-16mm materials will be sent to another 2 sets of sluice boxes for collecting the nuggets.

- A belt conveyor will send away the 16-70mm materials.

- After you select the big size concentrate gold from the centrifugal concentrator, you can send the left concentrate gold to the shaking table to separate again to get more pure concentrate gold.

- The trommel scrubber, centrifugal concentrator, and shaking table can change to different models and increase quantity according to different capacities.

- The sluice box can be designed with different lengths and widths like 2m,4m,6m length, 1m width, or 0.5m width.

The capacity for this washing plant can be customized as per request such as 10tph, 50tph,100tph, 150tph, etc.