Ghana 100TPH Alluvial Gold(With Clay) Washing Plant

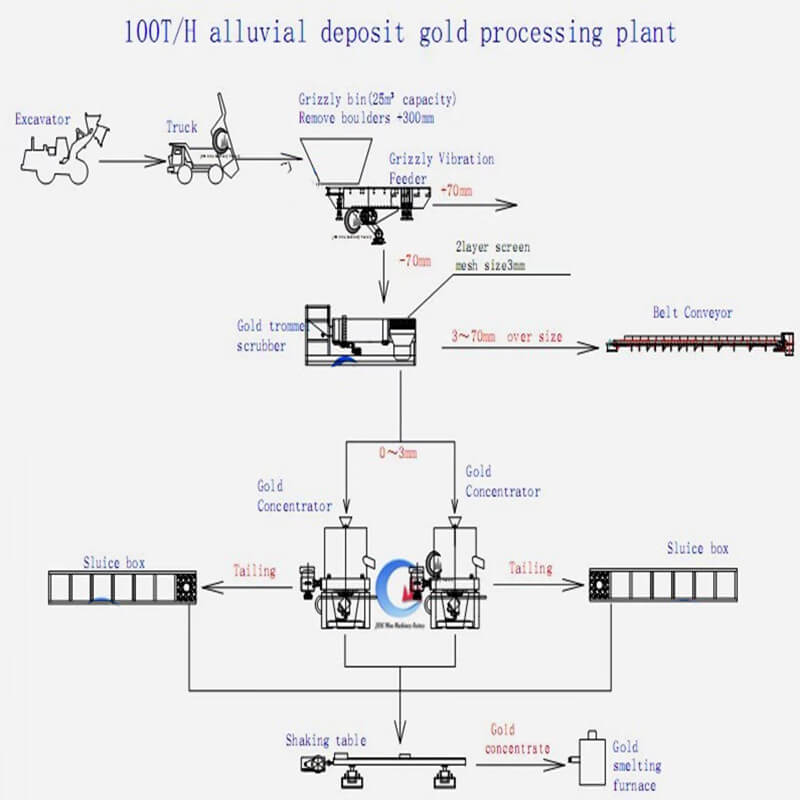

JXSC has provided a successful 100TPH alluvial gold washing plant in Ghana. We design the gold wash plant process flowchart & plant layout drawing according to ore conditions, provide a complete set of plant machines and send Chinese engineers to the mine site for plant installation & commissioning guidance.

Alluvial Gold Washing Plant Project Case

Introduction

Minerals: Alluvial Gold

Capacity: 100 TPH

Feeding Size: 4mm

Process: The raw material is the alluvial gold with sticky clay, so JXSC uses Gold Trommel Scrubber to wash the gold. And the gold grader needs to reach 80% above.

Solutions & Process

- The raw material is with sticky clay, so we use a trommel scrubberto wash the sand and sieve out some bigger particles.

- Then the undersize slurry from the trommel scrubberwill go to the gold centrifugal concentrator by gravity, for the primary concentration of gold.

- The concentrate ore from the centrifugal machine will go to the shaking table for final separation, then can get very pure gold.

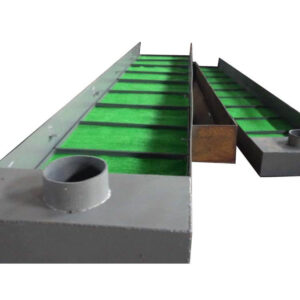

- The tailings from the gold centrifugal concentrator comes to a gold sluice boxto get some gold from the tailing.