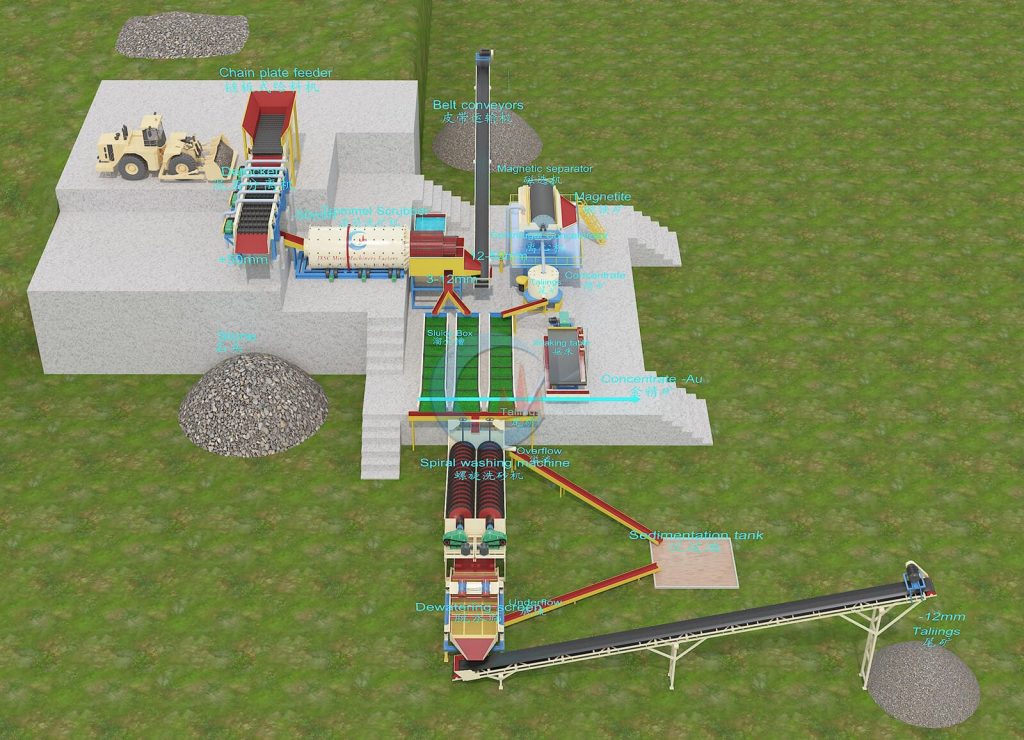

Ethiopia 200 TPH Alluvial Gold Processing Plant

JXSC has provided a successful 200TPH alluvial gold processing plant in Ethiopia. We design the ore process plant flowchart & plant layout drawing according to ore conditions and offer a complete set of plant machines.

Alluvial Gold Processing Plant Project Case

Introduction

Minerals: Alluvial gold with sticky clay

Capacity: 200 TPH

Process: Feeding -> Washing -> Magnetic separation -> Gravity separation -> Washing -> Dewatering

Solutions & Process

Gold Processing Plant

This setup is an alluvial gold process plant.

The loader feeds the raw material into the hopper, and the stone enters the plate feeder from the lower part of the hopper; the material is into the Derocker, and then fed to the rotary scrubber evenly, the larger than 50mm scrap will be separated by Derocker and transferred to the ground as a waste pile.

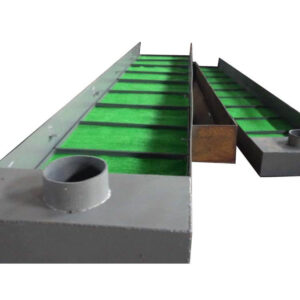

0-50mm will feed to the rotary scrubber, we made 2 screens on the rotary scrubber, 3mm, and 12 mm respectively. After washing and screening, transport 12-50mm material as waste sand by belt conveyor. The 3-12mm material will flow to 2 sets of gold sluice boxes to catch the gold particles.

The 0-3mm material will be input into the slurry tank. We use a slurry pump to pump the last 0-3mm material onto the wet drum magnetic separator to remove black sand(Magnetite).

After removing Magnetite, the tailings will feed to the gold centrifugal concentrator. The centrifugal concentrator can concentrate gold particles of 0-3mm.

The tailings will flow to the sluice box to catch again if there are gold particles.

The concentration after the gold centrifugal concentrator enters the shaker table through the pipe, the shaking table can concentrate the gold powder between 0-2 mm. Finally, use a gold melting furnace to get the gold bar(If you request, we can offer it). After getting all the gold concentrates, the tailings from 3 sets of sluice boxes will be sent to a spiral sand washer, and then a belt conveyor will send the 0-12mm tailing dry sand, the overflow is the clear water can be used again on trommel scrubber or sluice box, the clear water will flow to sedimentation tank.

The 0-3mm sand is minimal, so there is one more dewatering screen to dewater again. Finally, use one belt conveyor to send the tailing dry sand.