Congo 40 TPH Tantalum-Niobium Process Plant

JXSC has provided a successful 40 TPH tantalum-niobium process plant in Congo. We design the separation process plant flowchart and plant layout drawing according to the mineral ore’s conditions and offer a complete set of plant machines.

Tantalum-Niobium Process Plant Project Case

Introduction

Minerals: Alluvial and rock mixture type tantalum-niobium ore with sticky clay

Feeding Size: <120mm

Capacity: 40 TPH

Process: Feeding -> Washing & Screening -> Gravity Separation -> Crushing & Grinding -> Magnetic Separation

Solutions & Process

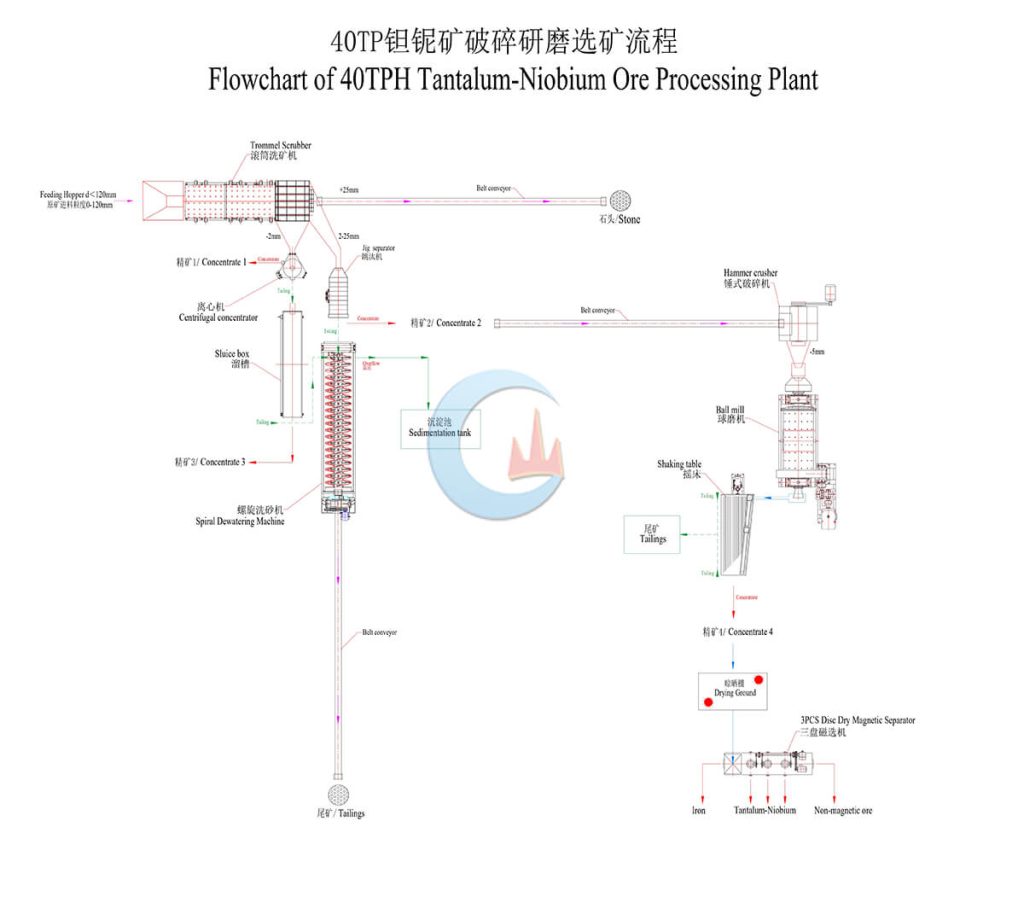

Tantalum-Niobium Ore Processing Plant Flowchart

This setup is a 40 tons per hour alluvial and rock mixture Tantalum-Niobium Ore processing plant. It is configured with a rotary scrubber, jig concentrators, centrifugal concentrators, shaker tables, sluice box, belt conveyors, ball mill, hammer crusher, spiral sand washer, etc. The process is as below:

- The plant will begin from the rotary scrubber with a hopper. The hopper also can be made with a grizzly bear to screen the much bigger rocks. Since there’s a lot of sticky in the raw ore, we suggest using a trommel scrubber to wash away the sticky clay. If you are raw or without too much sticky clay. You can use a Trommel screen. Here, the scrubber has 2 layers of screen, 2 mm, and 25mm. Therefore, rocks more than 25mm will be transferred together. Then the less than 2mm materials will go to a centrifugal concentrator. The tailing from the concentrator will go to the sluice box to gather concentrate again.

- The 2-25mm materials will go to the jig separator. The jig concentrator mesh size will be 2mm. Then the 0-2 mm sizes below the mesh from the jig concentrator and tailing from the sluice box will be sent to a spiral sand washer for dewatering. After that, the materials will be sent away by a conveyor belt. The 2-25mm materials above the mesh will be sent to a hammer crusher by belt conveyor to crush to be less than 5mm. The less than 5mm materials will go to the ball mill to grind to be 0-1 mm. After that, you need to feed the 0-1 mm materials into a shaker table to separate and collect the concentrated ore.

There are too many magnetic ores(like magnetite, hematite, etc) inside the concentrate ores, we can dry your concentrate first then use the three disc dry magnetic separator to remove them and get the final concentrate Tantalum-Niobium ores.