Congo 100TPH Placer Tin Ore Process Plant

JXSC has provided a successful 100TPH placer tin process plant in Congo. We design the tin process plant flowchart & plant layout drawing according to ore conditions, provide a complete set of plant machines and send Chinese engineers to the mine site for plant installation & commissioning guidance.

Placer Tin Ore Process Plant Project Case

Introduction

Minerals: Placer tin with clay, and contains small amounts of lead, zinc

Capacity: 100 TPH

Grade: 2-4%

Feed Size: Raw material 0-50mm, among them the tin ore size 0-3mm (15%), 3-12mm (50%), 12-20mm (35%)

Constituent analysis:

Sn 40.6%, U 0.03%, Rb 0.05%, Pb 0.5%, Pt 0.06%, As 0.08%, Hg 0.03%, Zn 0.04%, Cu 0.02%, Fe 3.1%, Mn 0.5%, Cr 2.2%.

Solutions & Process

Placer Tin Process Plant

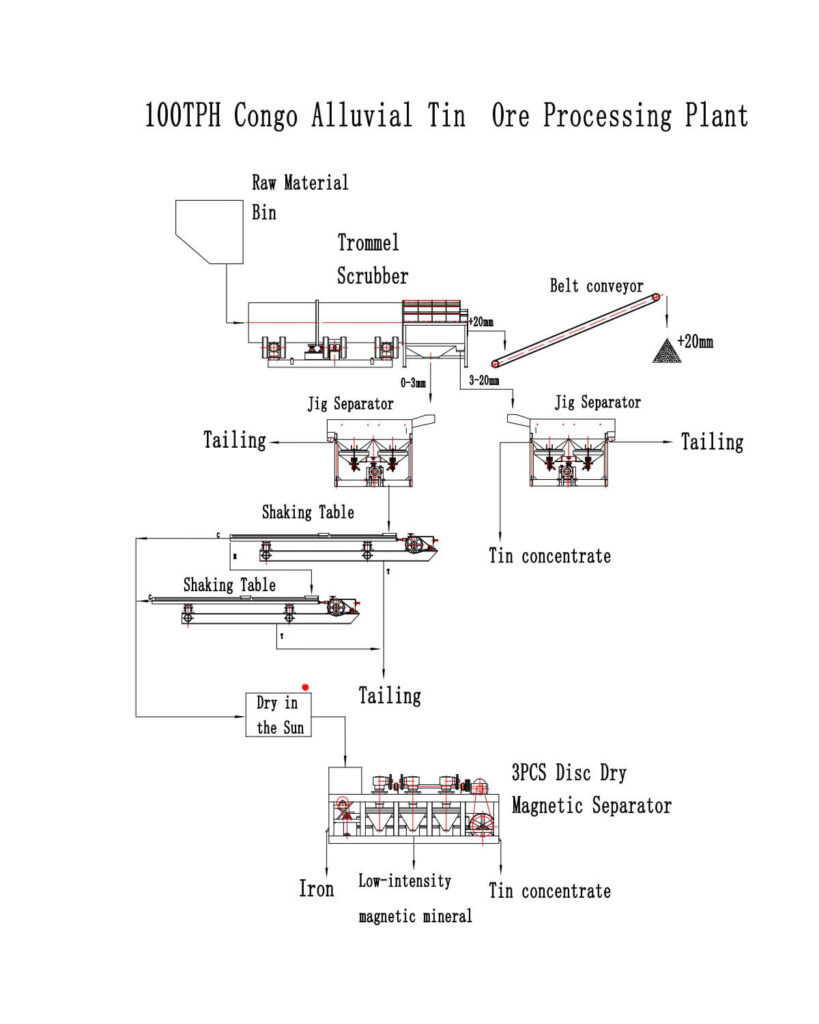

- The raw ore with clay comes into a trommel scrubber to wash and screen, the size larger than 20mm is tailing, which is delivered by a belt conveyor to the waste heap.

- The size of 3-20mm and 0-3mm from the trommel scrubber separately comes to a jig separator to jigging. We can get tin concentrate from the jig separator which jigging 3-20mm.

- The concentrate from the jig separator(jigging 0-3mm) comes to two shaking tables to improve the grade of the tin.

- Then dry the concentrate from the shaking table in the sun. And later send it to the 3pcs disc dry magnetic separator to separate iron and tin.

Placer Tin Process Plant Station