As an important industrial raw material, zircon sand is widely used in ceramics, the nuclear industry, the chemical industry, and other fields. The production process of Zircon Sand is mainly through the extraction of zirconium minerals (ZrSiO₄) from ores and a series of physical and chemical treatments, and ultimately obtain high-purity zircon sand, the production process is rigorous and complex.

Zircon Sand Production Process

1. Ore Mining

The ores of zircon sand are mainly derived from deposits of zirconium-bearing minerals such as bauxite and ilmenite. Common ore types include zircon sand ore (Zircon sand) and ilmenite ore (Ilmenite). When mined, the ore will be extracted with other minerals, which need to be separated from the zircon sand through the subsequent sorting process.

2. Raw Material Selection And Preparation

High-quality zircon sand ore needs to be selected as raw materials. The selection process of raw materials should ensure that the titanium content and radioactive elements of the ore meet the relevant national standards. This step is crucial because it is directly related to the quality of the final product.

3. Zircon Sand Beneficiation

Ore crushing and grinding process

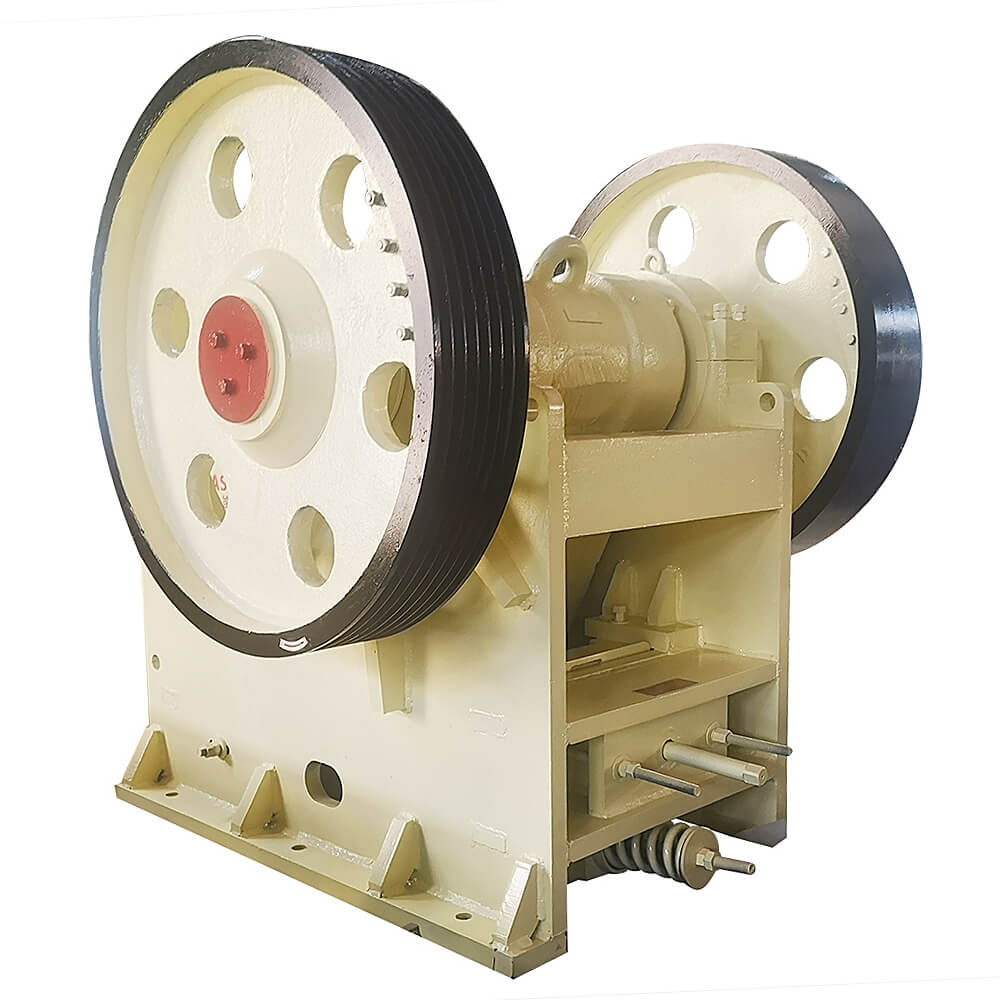

- Crushing: The mined ore will generally undergo preliminary crushing to make its particle size suitable for the next sorting operation. The jaw crusher or cone crusher is used to crush the raw ore into appropriate size particles. The particle size of the crushed ore should meet the requirements of subsequent pulverizing and re-election processing.

- Grinding: The crushed ore is finely ground by a ball mill to make its particle size below 0.5mm. The purpose of this step is to increase the specific surface area of the ore to provide better conditions for the subsequent process.

Screening and separating

After crushing, the ore will pass through a screening operation for initial separation based on the size of the particles. This process effectively removes large particles and impurity minerals, such as quartz sand and clay.

Zircon sand gravity separation

Zircon sand has a large specific gravity, so gravity sorting is a commonly used physical method in the sorting process. Zircon sand is separated from other minerals by equipment such as a shaking table, spiral classifier, chute, etc., utilizing the density difference between different minerals.

Zircon sand flotation

In the flotation process, finely ground zircon sand is mixed with chemicals and separated by flotation through a flotation machine. Flotation separates different minerals by using surfactants. Zircon sand has different flotation characteristics from other minerals such as ilmenite, and flotation further removes impurity minerals (e.g. bauxite, iron ore, etc.) mixed with zircon sand.

Zircon sand magnetic separation

Zircon sand is not strongly magnetic, but during its production process, it often contains some magnetic mineral impurities, such as magnetite and hematite. The presence of these impurities allows zircon sand to be effectively separated in the magnetic separation process. Magnetic separation beneficiation is one of the important means to purify zircon sand.

Zircon sand requires high purity and therefore all magnetic minerals need to be removed. In this process, magnetic separation equipment (e.g., high-intensity magnetic separator) is used to separate the impurities containing magnetic minerals (e.g., magnetite) and further improve the purity of zircon sand. After crushing and grinding, the material enters the magnetic separator. In the magnetic separator, the material is subjected to magnetic field force, and the magnetic mineral impurities are adsorbed on the magnetic system, while the non-magnetic zircon sand particles are discharged through the magnetic separator.

3. Chemical Treatment

Some zircon sands also require acid or alkaline leaching to remove residual iron, aluminum, and other impurities from the ore. Chemical reactions can further improve the quality of zircon sand, especially when it is needed for high-tech industries (e.g. nuclear energy, aerospace, photovoltaics, etc.).

- Roasting and leaching process

After magnetic separation and flotation, the ore enters the roasting process. Roasting is one of the key processes in the production of zircon sand, through high-temperature roasting to make the oxides and water compounds in the ore decomposition. Then leaching separation is carried out to obtain the leach solution of zirconium hydroxide, which contains zirconium compounds. - Zirconium hydroxide processing

The zirconium hydroxide slurry undergoes a series of filtration, crystallization, drying, and other processing procedures to obtain the final zircon sand product. In this step, strict control of product quality is also required to ensure that it meets national standards and customer requirements. - Sintering and preparation of compounds

In addition to the basic manufacturing process mentioned above, some manufacturers also use the sintering method to prepare zirconium compounds. Among them, the NaOH sintering method is a common industrial preparation method. By decomposing zircon sand with sodium hydroxide, then leaching with sulfuric acid, ammonia precipitation, sulfate washing, hydrochloric acid leaching, and other steps, ZrOCl2-8H2O is ultimately obtained. there are also methods such as Na2CO3 sintering, calcium carbonate sintering, and calcium oxide sintering, but their applications are relatively few. - Zirconium compound purification

In order to further improve the purity of zirconium compounds, but also need to carry out purification operations. In the purification process, chemical methods such as solvent extraction, ion exchange, etc., can be used to remove impurity elements to obtain high-purity zirconium compounds.

5. Drying And Packaging

After physical and chemical treatment, the zircon sand is usually dried to remove water and achieve the appropriate moisture content. The dried zircon sand is then bagged and prepared for delivery to downstream users.

The quality of zircon sand is very important, especially for high-end applications. The production process requires rigorous quality testing to ensure that its purity, particle size, and other physicochemical properties meet the requirements.

The production process of zircon sand includes the steps of ore mining, crushing, screening, separating (gravity separation, flotation, magnetic separation), chemical treatment, drying, packaging, etc. The technical means involved include physical sorting and chemical separation. With the progress of science and technology, the purification technology of zircon sand is constantly developing, and the production efficiency and product quality are also improving. If you have a more in-depth interest in the equipment or technology of a certain process, please contact us.