Tantalum and niobium are non-ferrous metals with a high melting point, possess many high-quality properties, and are key raw materials for industrialization. Tantalum and niobium have a high melting point (2996°C for tantalum and 2468°C for niobium), good ductility, very low vapor pressure, strong corrosion resistance, and high heat transfer rate. They are key raw materials for the industrial production of electronic devices, atomic energy, space navigation, steel, chemical plants, etc.

Tantalum-niobium ore is a very rare natural resource. Its water content in iron ore is very low. The raw tantalum-niobium ore cannot directly use for industrial production. The smelter must purify it to improve the quality.

How to improve the grade of tantalum niobium ore?

It requires using tantalum-niobium ore beneficiation technology and tantalum-niobium ore mining machinery and equipment. China’s tantalum-niobium ore is mostly with complex properties and low decorative materials. In contrast, Africa’s tantalum-niobium ore is mostly placer, with single properties, simple beneficiation technology, and low investment in equipment.

Tantalite-copper Niobium Process Plant in Africa

Tantalite-niobium copper ore is mostly iron ore of polymetallic materials such as tantalum, niobium, tin, tungsten, lithium, and arbor. It has the characteristics of low raw ore grade, complex mineral composition, high mineral relative density, brittle, and easy to break. The key to the process plant is to choose solutions such as gravity separation, magnetic separation, and flotation.

Choosing the gravity separation step is the key to the rough separation of tantalite-copper niobium ore. It also uses the processing as: gravity separation – flotation – gravity separation; gravity separation – flotation, or gravity separation – magnetic separation equipment – gravity separation.

Gravity Separation

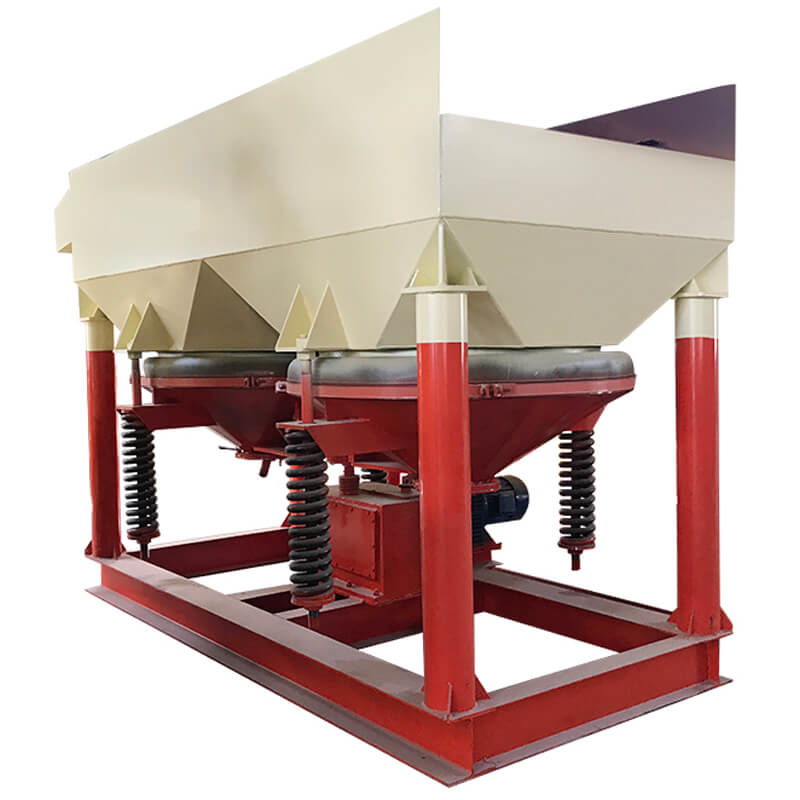

The raw tantalum and niobium mines mostly use grinding and multi-stage gravity separation. Generally, sorting equipment is added to the grinding control circuit to recover individual minerals in advance. Because tantalum-niobium placer is better separated by unique minerals, crushing and grinding are usually unnecessary. Before the selection, masonry and river pebbles are removed first, followed by rough separation. The jig concentrator roughly separates coarse crystal tantalum and niobium ore, and the shaking table extracts the rough concentrate. The jig concentrator or shaker roughs the fine crystal tantalum and niobium ore, and the shaking table extracts the rough concentrate again. The characteristics of this step are small investment, good effect, low cost, and less air pollution.

Flotation

Tantalum niobium slime can sort by flotation process. Before flotation, more than half of the sludge is deslimed with small-diameter cyclones or suction filtration smelters. Then alkyl sulfosuccinate is used as a collector, and sodium silicate and hydrochloric acid are used as regulators. At the standard of PH2-3 to carry out the flotation, the flotation concentrate uses the Holman slime shaker-horizontal transmission belt coal hopper for separation and extraction; or uses butadiene phosphonic acid as a collector, sodium fluorosilicate, and salt as a regulator, at PH6 Flotation is carried out under the standard, and the flotation concentrate is selected and extracted with a vibrating drive belt coal hopper or a countercurrent drive belt coal hopper. Solve according to the left and right methods, and you can get tantalite or niobium copper ore concentrate. The characteristic of this step is that the sorting index value is high. Still, the water content of tantalum and niobium in the removed fine mud is mainly close to the taste of the original ore, the amount of medicine used is large, and the product cost is high.

Magnetic Separation

The beneficiation and extraction of tantalum and niobium ore require the comprehensive application of strong magnetic separation equipment, electric separation, and other smelting methods, which can further purify the jig concentrate to meet industrial production requirements. The critical point of the tantalum-niobium ore smelter lies in the roughing process. Due to the extremely low grade of raw ore, it is necessary to use high-efficiency, environmentally friendly, energy-saving, and low-consumption mining machinery and equipment to carry out pre-selection and tailings and reduce the working pressure of the extraction equipment. To obtain the best economic benefits, if directly using the extraction equipment for smelting the washed tantalum and niobium ore, achieving the ideal efficiency and energy consumption requirements is difficult.

Africa Tantalum Niobium Ore Contains Stick Clay

The Africa tantalum niobium ore’s mud content is vast and has much stick clay. To purify the tantalum-niobium ore, you must first wash the ore and remove the mud. The washing machine uses a rotary scrubber and spiral washing machine. First, use the rotary scrubber to wash the raw ore and screen out lumpy gravel. The sediment enters the spiral washing machine for further cleaning and desliming and then enters the next process.

JXSC Mineral is a professional tantalum-niobium ore mining machinery and equipment manufacturer. Our factory has a rich and colorful social experience in tantalum-niobium ore process plants. We can carry out processing plant tests for customers free of charge and design concepts for tantalum-niobium ore smelting plant systems. Welcome to the call for a consultation for software solutions and machine equipment configuration.