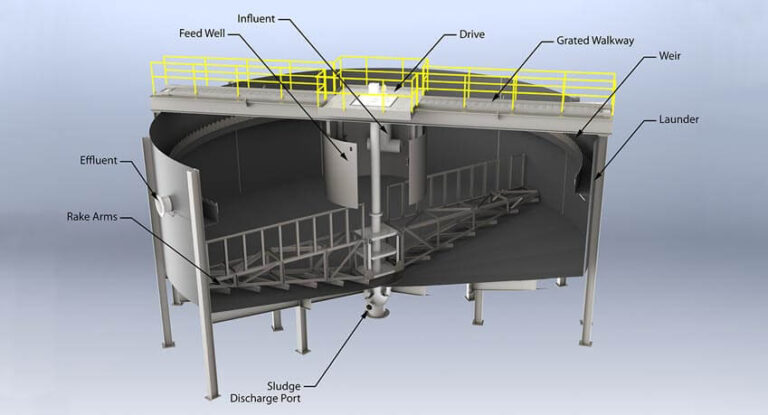

Thickener is one of the commonly used equipment in mineral processing plants, which can be used for dehydration, drug removal, concentration and other operations. With the continuous improvement of mineral processing requirements, its abnormal vibration directly affects the daily production work of the mineral processing plant. The vertical deviation of the central column of the thickener, the horizontal deviation of the driving device, the different level of the rake frame, the asynchronous driving mechanism, the damage of the driving gear or bearing, etc. It may cause the problem of abnormal vibration of the thickener to become increasingly prominent. In response to the above problems, we continues to improve the thickener. We will investigate the main reasons for the abnormal vibration of the thickener and formulate corresponding solutions.

1. The deviation of the verticality of the central column is large

The vertical misalignment of the thick machine center column directly results in the horizontal and balanced operation of the thick machine rake frame. After the center column is tilted, the long rake frame is at a low point due to the tilt. The long rake frame on the other side is always at a high point, making the rake frame overall inclined. The inclined rake frame is in a high and low state during the rotation process, which is prone to abnormal sound and vibration. In addition, this vertical deviation will also cause uneven force on the drive gear of the thick machine, which is prone to abnormal sound during long-term operation under this condition, and may also cause damage to the drive gear.

- Detection methods: For the emptying machine with the center column as the core, four measurement points are determined on the outside of its bottom with the 4 vertices of the square as a model. Measure from the top of the central column with four measurement points corresponding to the lead vertical to determine whether the central column is vertical or deviated. For a drain thickener, select multiple measurement points on the side walls of the thickener at certain intervals. By measuring the height difference of the rake, it is possible to determine whether there is a deviation in the center column and the direction of the deviation.

- Solutions: The problem of center column deviation is solved by adjusting the backing plate at the connection of the center column.

2. Level deviation of thickener drive

During the installation process, there was a horizontal deviation problem in the thickener’s drive. Since the rotating mechanism of the thickener is connected with the driving device, the rotating mechanism is directly deflected during operation, resulting in abnormal vibration of the thickener. In the long run, abnormal rotation caused by deflection of the drive can cause permanent damage to its internal transmission components.

- Detection method: The main support structure of the drive device or the upper plane of the large gear is used as the detection body. Four points in different directions are found as the measurement plane of the measurement reference, and the four points are statically detected by the spirit level. Then collect the dynamic detection values of 4 points, and determine the horizontal deviation of the drive device by comparison.

Solution: Solve the problem of abnormal vibration, and eliminate the horizontal deviation by adjusting the angle between the driving device of the thick machine and the central column.

3. Thick machine rakes are not at the same level

Thickeners usually have two long rakes and two short rakes. The enrichment process is achieved by the continuous rotation of the rake. Due to the different slurry concentrations, the forces experienced by the rake during operation are also different. Because the machine cantilever is long, long-term operation can easily cause the four rakes in the machine to be not on the same level. If the machine runs under such fault conditions, the rake will float up and down due to the uneven force during the rotation process, resulting in abnormal vibration of the machine, affecting the uniform settlement of the pulp and reducing the quality of the overflow water.

- Detection method: Empty the concentration machine, and determine four measurement points according to the different directions of the side wall of the concentration tank. Determine the position of the rake arm corresponding to each point by the theodolite, determine whether all the rake arms work on the same horizontal plane, and how much deviation there is.

- Solution: The connection position of the problem rake arm should be adjusted in time according to the test results, so that it is always on the same level, so as to eliminate the fault.

4. Unsynchronized drive mechanism

The thickener generally realizes its rotary drive through 2-4 driving heads, and each driving head works independently to provide power for the rotation of the thickener. When the drive head enters an abnormal working state, it will cause insufficient driving force for equipment operation, or blockage of the drive, or failure of the transmission gear of the drive head, resulting in forced dragging and vibration of the thickening machine.

Detection method and solution: disassemble the thick machine drive device, check multiple drive heads, determine whether the equipment drive device is synchronized, and then repair and correct the problem drive head to solve the asynchronous problem.

5. Damaged transmission gear or bearing

Without regular maintenance and lubrication, equipment gears or bearings can be damaged by uneven forces. The faulty component will produce obvious vibration and abnormal noise during operation. If it is not dealt with in time, it may lead to abnormal shutdown of the equipment, thick machine rakes and other failures.

Detection method and solution: directly repair the abnormal sound part and remove the fault.

6. The rake frame and the cage structure are not strong enough

During the operation of the thick machine, the rake frame and the rotating cage are subjected to greater force, the larger the scale, the longer the thick machine rake frame, and the greater the force of the rake arm. The rake and tumbler with insufficient strength will elastically deform when the slurry accumulation layer is running, causing the tumbler to deviate to one side and causing the whole equipment to shake.

Detection method and solution: Regular maintenance of equipment is carried out, and if the deformation of rake and turret is found, brackets can be appropriately added, and the connection strength of joints can be strengthened.

The above are the six main reasons and solutions for the abnormal vibration of the thickener. It is recommended to consider the production environment, process conditions, investment costs and other factors to select the appropriate thickener.

Contact us, a professional and qualified manufacturer, the equipment has a long service life and avoid economic losses.

Trommel screen

Trommel screen