Recycling construction waste resources is an effective way to transform construction waste into useful products. Most can be reused as renewable resources after being crushed, screened, removed, and dusted by professional equipment. Construction waste refers to the slag, abandoned soil, materials, silt, and other wastes generated during the construction, laying, demolition, and repair of various buildings, structures, pipe networks, etc. by construction units or individuals. According to the different sources of garbage, construction waste can be divided into construction waste and demolition waste (the composition of the demolition waste of old buildings includes concrete, dust, soil, gravel, stone, bamboo, wood, bricks, metal, asphalt, sand, other organic matter, plastic pipes, glass and other materials.), classified by composition, construction waste is divided into slag, concrete blocks, gravel blocks, brick and tile fragments, waste mortar, mud, asphalt blocks, waste plastics, waste metals, waste bamboo and wood, etc.

The Current Situation of Construction Waste in China

Construction waste production

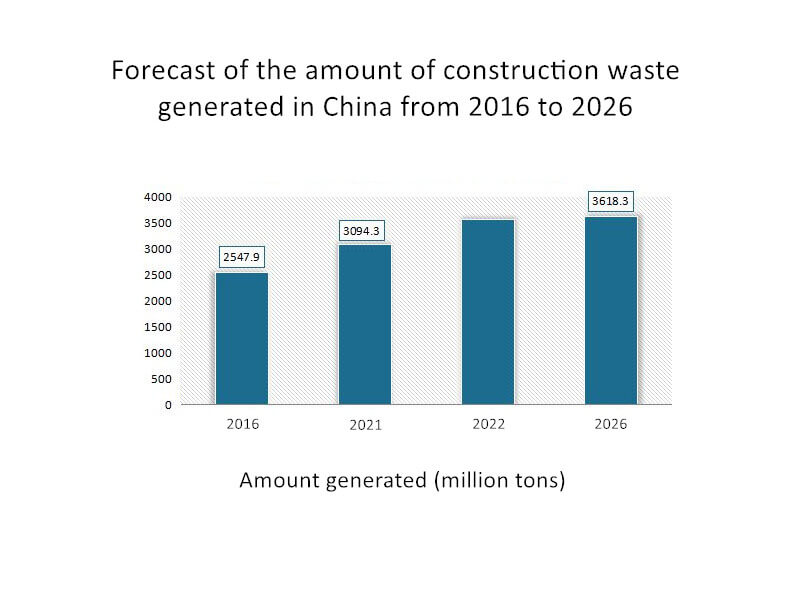

With the rapid advancement of urbanization in my country and the vigorous development of the construction industry, the amount of construction waste generated during the construction process has increased significantly and has become the largest single category of urban waste. In 2023, my country’s construction waste production will be about 3.48 billion tons. Future growth forecasts are expected to reach 4 billion tons in 2025 and exceed 4 billion tons in 2026.

Construction waste treatment volume

In the process of urbanization in my country, the construction industry has developed rapidly, the scale of construction has continued to expand, and the resulting construction waste has become an important factor affecting the ecological environment. According to the calculation of the China Urban Environmental Sanitation Association, the annual generation of construction waste in large and medium-sized cities in my country has exceeded 2 billion tons in recent years, which has remained high. In terms of treatment volume, the current construction waste treatment volume is about 1.75 billion tons.

Although my country’s construction industry is currently in a period of rapid development, the resource utilization rate of construction waste is less than 10%. China’s construction waste has not been effectively treated and utilized in the past few years, resulting in a huge stock of construction waste in my country. The huge and increasing amount of construction waste has stimulated the growth of demand for construction waste treatment. Compared with the construction waste recycling rate of some developed countries, which is as high as 90%, the market still has a lot of room for improvement. According to analysis, the recycling of construction waste resources can save a lot of resources, save the process of building material reproduction, protect the ecological environment, and generate economic benefits, which has become the development direction of construction waste treatment.

Turning Waste Into Treasure: Green Treatment of Construction Waste

Faced with the various problems brought by construction waste, we are not helpless. In fact, through scientific and effective treatment and utilization, construction waste can be completely turned into treasure and become a new driving force for promoting green urban development.

1. Source reduction

During the design and construction stage of the building, priority should be given to the use of easily recyclable or renewable materials to reduce unnecessary waste and improve the efficiency of material use.

2. Classification and collection

Set up special classification and collection containers at the construction site, and conduct preliminary classification according to the different properties of the materials to lay the foundation for subsequent resource utilization.

3. Recycling

Use treated concrete blocks, brick tiles, and other inorganic materials as recycled aggregates to produce new building materials, such as recycled concrete, recycled bricks, etc. At the same time, valuable materials such as metals and wood should also be recycled and reused.

4. Energy utilization

For construction waste that cannot be directly reused, high-temperature incineration and other technologies can be considered for energy utilization, and the heat generated by incineration can be converted into electricity or thermal energy.

5. Landfill treatment

For construction waste that cannot be recycled, a suitable landfill should be selected for landfill treatment, and the site selection, design, construction, and operation of the landfill should be ensured to comply with relevant environmental protection requirements.

Modular Intelligent Production System- 5 Core Equipments Create a Golden Industry Chain

The modular system breaks down the construction waste treatment process into multiple independent functional modules (such as crushing, screening, separating, dust removal, etc.), enabling flexible combination and rapid deployment.

Core Equipment – Jaw Crusher

Effect

- Primary crushing: Coarse crushing of large blocks of concrete, bricks, and other hard materials in construction waste, with a crushing ratio of 4-6 and a processing capacity of 70-100 tons/hour.

- Wide adaptability:It can process concrete blocks containing steel bars and separate steel bars and aggregates through extrusion and shearing.

Advantages

- Simple and durable structure: It adopts a symmetrical V-shaped cavity design, and the jaw plate has strong wear resistance and a low maintenance cost.

- Flexible mobility:The vehicle-mounted or crawler jaw crusher can process construction waste on-site to reduce transportation costs.

- High crushing efficiency: The feed opening width is more than 350mm, suitable for large blocks of materials, and the particle size after coarse crushing is ≤

Core Equipment – Vibrating Screen

Effect

- Material classification: The crushed mixture is sorted by particle size, such as a double-layer bar screen to achieve coarse screening (separation of large impurities) and fine screening (separation of recycled aggregates).

- Optimize resource utilization: The screened aggregate can be directly used for roadbed, brick making, or recycled concrete.

Advantages

- High precision and efficiency: The vibration screening machine achieves precise particle size separation by adjusting the vibration parameters (such as a 30% increase in screening efficiency).

- Adapt to complex materials: The bar screen remains stable when handling high humidity and sticky garbage.

- Modular combination: It can be linked with the crusher to form a closed-loop circulation system to reduce over-crushing.

Core Equipment – Iron Remover

Effect

- Metal impurity separation: remove metal materials such as steel bars and iron wires from construction waste to avoid damage to subsequent equipment.

- Improve product purity: ensure that recycled aggregates do not contain metal residues and meet the requirements of building materials production.

Advantages

- Automated operation: The electromagnetic iron remover is linked to the conveying system, and the separation efficiency reaches more than 95%.

- Economic value: The recovered metal can be sold as scrap to increase revenue.

Core Equipment – VSI Sand Making Machine

Effect

- Aggregate shaping: Crush and shape the recycled aggregate to produce high-quality recycled sand (rounded particles and controllable powder content).

- High added value utilization: Recycled sand can be used to prepare concrete above C30 or environmentally friendly bricks.

Advantages

- Particle shape optimization: Vertical shaft impact crusher uses centrifugal force to cube the aggregate and improve the compressive strength.

- Low energy consumption: VSI sand-making machine adopts a closed rotor design, which reduces energy consumption by 20% compared with traditional equipment.

- Environmental compatibility: The matching dust removal system can reduce fine dust.

Core Equipment – Intelligent Environmentally Friendly Dust Collector

Effect

- Dust control: Capture fine particles (PM2.5-PM10) in crushing, screening, and other links to reduce air pollution.

- Health protection: Reduce dust concentration in the working environment to protect the health of workers.

Advantages

- High-efficiency filtration: The bag filter has a filtration efficiency of 99.9%, and the electrostatic precipitator is suitable for high humidity conditions.

- Intelligent control: Real-time monitoring of dust concentration and adjustment of air volume, energy consumption is 30% lower than traditional equipment.

- Compliance: Meet the requirements of environmental protection regulations such as the “Comprehensive Emission Standards for Atmospheric Pollutants”.

300,000 Tons Per Year Construction Waste Recycling Production Line Cost

Investment return calculation

- Equipment investment: about 12 million yuan

- Annual profit: 40 million to 60 million yuan (calculated based on a price difference of 300 yuan/ton)

- Payback period: only 1.8-2.4 years

Cost

- 30% energy consumption (permanent magnet synchronous motor energy-saving technology)

- 50% labor (intelligent unmanned control)

- 20% capacity utilization (7×24 hours continuous production)

Green ecological value

- Carbon reduction effect:1 ton of construction waste processed ≈ 0.8 tons of CO₂ reduction

- Resource recycling rate: Aggregate recycling rate 92%, comprehensive utilization rate of waste 100%.