A roll crusher is a kind of equipment used for medium and fine crushing of medium hardness materials, which is widely used in mining, chemical, building materials, and other industries. It squeezes materials with two relatively rotating rollers, featuring a large crushing ratio, low energy consumption, easy operation, etc. It is suitable for handling limestone, coal, and other materials. In the market, the roller crusher has become one of the important equipment for small and medium-sized mines and gravel production lines due to its advantages of high efficiency, energy saving, and easy maintenance, and the market demand is stable and the technology matures gradually.

Introduction of Roller Crusher

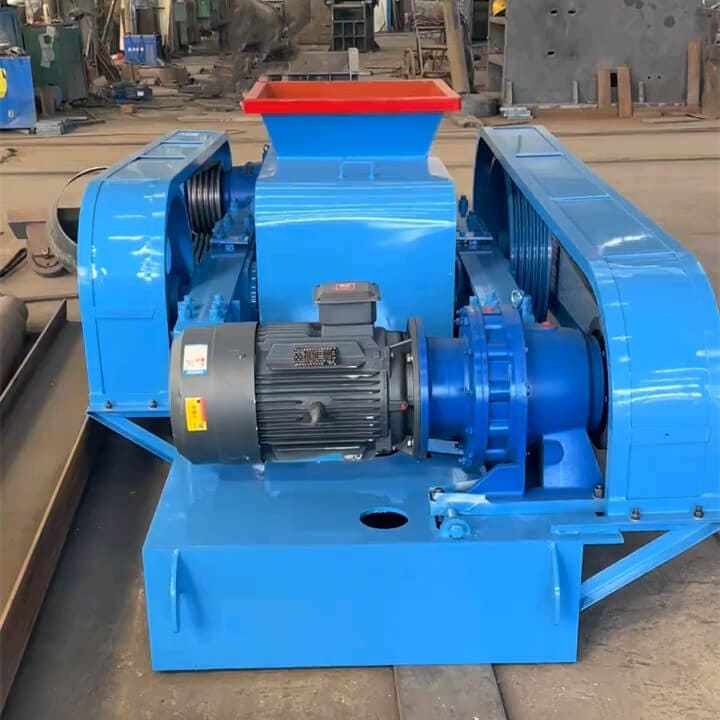

The roller crusher, also known as a double roller crusher, is a kind of mining machinery mainly used for crushing ores. It has the advantages of small size, large crushing ratio (5-8), low noise, simple structure, easy maintenance, etc. The particle size of the crushed material is uniform, the over-crushing rate is low, maintenance is convenient, and overload protection is sensitive, safe, and reliable.

Working Principle

The material enters from the inlet of the roller crusher and falls between two relatively rotating rollers. During the rotation of the rollers, the material is crushed by extrusion, shearing, and stretching. When the material reaches the required size, it will be discharged from the discharge port.

Adjustment of discharging granularity: the two rollers are equipped with a wedge or gasket adjusting device, the top of the wedge device is equipped with an adjusting bolt, when the adjusting bolt pulls the wedge upward, the wedge will push the movable roller away from the stationary wheel, i.e., the clearance between the two rollers becomes larger, and the discharging granularity becomes larger, when the wedge goes downward, the movable roller will make the clearance between the two wheels smaller under the action of the pressing spring, and the discharging granularity becomes smaller. The gasket device is by increasing or decreasing the number or thickness of the gasket to adjust the size of the discharge size when the increase of the gasket when the gap between the two rollers becomes large, when the decrease of the gasket when the gap between the two rollers becomes small, the discharge size becomes small.

Advantages

- Low noise& reliable performance

Roller crusher technology production strength, and stable and reliable performance, can reduce noise pollution, and play an effect of environmental protection. - High production efficiency&large capacity

The crushed product is cubic, with low needles and flakes content, no internal cracks, and fine particle size, which improves the production quality and efficiency. - The long service life of wearing parts & low loss

Roller skin has a long wear cycle, and the wear parts are made of new type high strength wear-resistant materials, which can crush high hardness materials with small loss and long service life and can bring considerable economic benefits for customers.

Selection of Roller Crusher

Due to the rapid development of mining industry, there are more and more users using roll crusher. Roll crusher is the key equipment to crush the materials, with a large crushing ratio, simple structure, strong production capacity, uniform size of the finished product, easy maintenance and so on. To choose a good roll crusher, it is still recommended to visit the plant directly to inspect the equipment, the following JXSC Mineral organized four points should be noted when buying, hope to help you buy good equipment.

1. Quality

Buy equipment quality is the key, it is recommended to buy roll crusher users, learn more about the quality of the equipment, such as whether its wearing parts are high manganese chrome material, focus on the quality of the equipment, and do not want to cheap.

2. Crushing ratio

Each manufacturer produces a different crushing ratio of the roll crusher, too coarse or too fine is not good, you can bring part of the material before buying a test run to investigate.

3. Energy consumption

We should consider the economic benefits at the same time, but also consider the issue of energy consumption, roll crusher energy consumption is mainly concentrated in the crushing chamber, should pay attention to the degree of friction of each component, choose the low energy consumption of the roll crusher, more to ensure economic benefits.

4. Evaluation

Buy equipment should choose strong business strength, perfect after-sales service, reliable quality, good evaluation of large manufacturers. After-sales service is also guaranteed.

Maintenance of Roller Crusher

Roll crusher can be continuously extruded and circulated, which not only has high production efficiency, but also can deal with sticky and wet materials. Therefore, this equipment plays an important role in the development of chemical and metallurgical industries. The equipment requires frequent maintenance to minimize common failures and safety risks. It can also ensure the stability of the crushing production performance, extend the service life of the equipment, and create greater economic benefits for you. The next step we will introduce the daily maintenance of roller crusher roll surface.

- When using roller crusher with sliding shaft, please check the clearance of roller bearing. The clearance between roller sleeve and journal is usually 1/1000 to 1.5/1000 of journal diameter, and the side clearance of bearing sleeve is 1/3 to 1/2 of the top clearance.

- Reasonable selection and addition of lubricating materials according to the structure of the equipment is the main aspect of equipment maintenance.Usually use two kinds of lubricating materials: grease and lubricating oil. Grease is easy to lubricate and is often used when the dust is dirty. Grease is easy to seal and prevent dust from entering the bearings.

- In order to ensure the normal operation of the crusher, the lubrication status of the bearings needs to be checked frequently. Sliding bearings are usually regularly refueled with oil cups or manually filled with thin oil, but rolling bearings are regularly lubricated and sealed.

- The roll surface of the roller crusher needs to be repaired frequently during the work, and the rollers are sometimes mounted on the frame of the roller crusher with smooth surface.If there is a depression or groove on the roll surface, the roll surface can be surfaced without removing the rolls.

- Toothed plates or rings of roll equipment can be replaced or turned over.The teeth are worn and must be replaced or repaired. Otherwise, the particle size of the damaged product is not uniform, power consumption increases, and the output decreases.

- The roll has a surface treatment device, can be directly repaired with the machine, the local luster roller crusher has an automatic axial reciprocation device of the roll, the roll surface wear is uniform.After the roll surface wear, the width of the discharge opening increases, you need to adjust the movable roll (single roll and jaw adjustment). When adjusting, the two rollers must be parallel to each other to prevent deformation.

As a piece of traditional crushing equipment, roll crusher follows the trend and keeps innovating, it can be applied in cement, the chemical industry, mining, metallurgy, coal mines, and other fields, which is popular among users because of the advantages of large feeding size, adjustable size, and low price.