According to mineral morphology, the gold mineral is divided into rock gold and placer gold. Generally, a ton of ore is mined to extract a few grams of gold. The alluvial gold is easy to mine, the process of rock gold mining is relatively complicated and difficult.

The following is the processing of two minerals containing alluvial gold and rock gold.

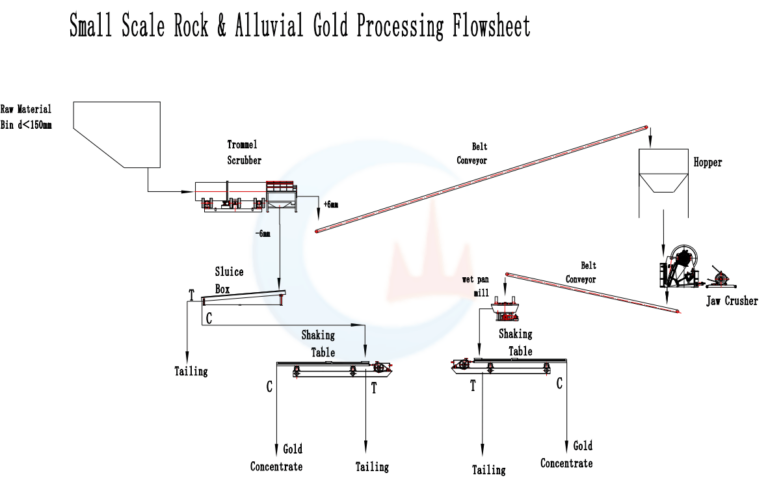

5TPH Rock Stone & Alluvial Gold Mixed Processing Plant

Introduction:

Raw Material: Rock Stone & Alluvial Gold Mixed

Capacity: 5TPH

Feed size: 0-150mm

Customer’s Requirements:

- The rock stone need to grind less than 1mm to release the inside gold. The gold deposit in alluvial type are very fine also less than 1mm.

- The raw ore material is purchased from the local mine owner.

- The investment is limited as a start, so start with a smaller scale while with easy operation first.

Processing Flowsheet:

Equipment List:

- Jaw crusher

- Wet pan mill

- Trommel scrubber

- Gold sluice box

- Shaking table 6S-4500

- Belt conveyor DT75-500

- Gold amalgamation

- Gold distiller

- Gold smelting furnace

Flowchart explanation:

1. All the raw ore feed into trommel scrubber for washing out the sticky clay and sieve out two different particles. The trommel scrubber with grizzly bar to separate out the bigger than 40mm;

2. The smaller than 2mm goes to sluice box to catch the nuggets or gold granularity first. The alluvial gold granularity size is less than 1mm, so we design the screen mesh with 2mm to make sure catch all the gold particles;

3. Then go to shaking table for separating the gold again to update the recovery rate;

4. The bigger than 2mm from the trommel scrubber will stack up accordingly;

5. Then go to jaw crusher with the first stage screening out material, which can crush the big stone into smaller parties around 20mm;

6. Then go to wet pan mill which can grind the smaller stone into powder less than 1mm to release the inside gold;

7. The output from wet pan mill will go to shaking table for separating the gold.

On-site:

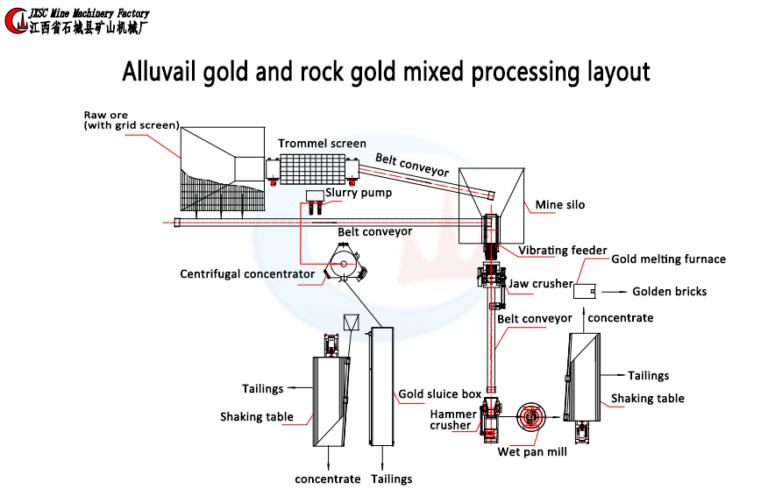

50 TPH Alluvial Gold & Rock Gold Processing Plant

Processing Flowchart:

Equipment List:

It is configured with a trommel screen, gold centrifugal concentrator, gold sluice box, belt conveyor, trough feeder, jaw crusher, hammer crusher, shaking table, and gold smelting furnace.

Flowchart explanation:

1. The rock stone part crushing around 5 tons per hour, the later stage for grinding & gold separation of the rock stone part is around 3 tons per hour;

2. The raw ore feed into the trommel screen for washing a few little clays and can separate the gravel or stone which need to crush & grind to get the inside gold, the separated gravel can transfer to the next jaw crusher by the belt conveyor. For this flowsheet, the trommel screen is designed with mobile wheels, which can easily move from one site to another site. Or you can choose a stationary one.The trommel screen designed with one layer screen;

3. The bigger than+6mm goes to the jaw crusher(Max input stone shall be less than 210mm), which can crush the big stone into smaller parties around 40-60mm;

4. The output from the jaw crusher goes to the hammer crusher via the belt conveyor. The hammer crusher crushes the smaller stone less than 10mm to wet pan mill for grinding;

5.The wet pan mill grinds the 10mm gravel stone less than 1mm to release the inside gold.

6.Since the grinding with 3 tons per hour, two shaking tables are required for the gold separation.

7.The smaller size 6mm from the trommel screen goes to a slurry pump, use two slurry pump to pump the slurry into gold concentrator for catching the gold first, the concentrates from the gold concentrator goes to shaking table for separating the gold again to update the recovery rate;

8. On this part, each gold concentrator matches one sluice box for the tailings. And two shaking tables for matching each gold concentrator accordingly;

9. All the collected gold concentrates after shaking the table will be sent to the gold smelting furnace for melting the gold bar.

How to choose trommel screen and trommel scrubber for gold washing equipment?

Both cleaning and screening functions can be combined, and one machine can be used for two purposes. Trommel screen is used for less mud content; Trommel scrubber is more suitable for cleaning ores with moderate difficulty, but not suitable for materials with less ores and more sludge.

Trommel screen

Trommel scrubber

The grade of gold in placer gold and rock gold mines is extremely low. In order to obtain high-grade gold, professional gold selection equipment is required to extract it through a professional gold selection process. The beneficiation work flow of placer gold mine mainly includes washing, crushing, grinding, screening, gravity separation and concentration.

JXSC will design complete set Flowchart and provide complete set gold processing plant machines & all accessories according to customer’s request. Contact us to know the list of gold mining machine price.