Cobalt (Co) is a silvery-white ferromagnetic metal. Cobalt has 27 protons and is sandwiched between iron and nickel in the middle of the periodic table.

Cobalt metal is hard, brittle, and ferromagnetic. Magnetism disappears when heated to 1150°C. It does not interact with water at room temperature. It is oxidized to form CoO when heated to 300°C or higher in the air and burns into Co 3 O 4 in white heat. Its melting point is 1,495°C.

Cobalt Demand

Why is there cobalt in mobile phones? Cobalt is found in lithium-ion batteries used in smartphones, tablets, and laptops. In the mid-20th century, people began to use lithium as the negative electrode of batteries. However, problems such as lithium dendrites may occur during the charging process, reducing the safety of the battery. Chemist John B. Goodenough discovered that cobalt made batteries safer and more stable. Lithium cobalt oxide batteries emerged at the historic moment and are widely used in portable electronic devices such as mobile phones and laptop computers. The electric vehicle boom has fueled a surge in cobalt demand. According to the International Energy Agency (IEA), demand could increase 6-30 times by 2040 compared to today.

Cobalt Mine Production and Reserves

The surge in cobalt demand raises concerns: Is our planet rich in cobalt? Can annual cobalt production meet demand?

Unfortunately, global cobalt resources are uneven, and the world’s cobalt mine production is scarce. According to preliminary data released by the United States Geological Survey (USGS), global cobalt production in 2021 will be approximately 170,000 tons, which is in the hands of a few companies.

The Democratic Republic of the Congo (Congo) holds more than 50% of global cobalt reserves. The rest are spread across several countries, including Australia, Cuba, Zambia, the Philippines, Canada and Russia. Congo supplies more than 70% of the world’s cobalt, ranking first. China is the largest cobalt refining and consumer country, accounting for 67% and 52%, while cobalt production only accounts for about 1%.

Cobalt Mining and Processing

In nature, cobalt is primarily associated with minerals such as copper, nickel, and iron. There are no independent cobalt deposits. Cobalt is mainly a by-product of copper and nickel mining, which makes it harder to obtain. Congo is the largest cobalt supplier. I will introduce several widely used and efficient cobalt beneficiation methods in the Congo copper-cobalt mineral belt.

Crushing Process

Severe slime is a distinctive feature of copper oxide ores. Heavy rainfall occurs during the local rainy season (November to March), making the ore have a high water content and more viscous. Considering factors such as ore properties, natural conditions, and production stability, semi-automatic ball mill crushing circuits (SABC) have been commonly used in the crushing process of newly constructed mineral processing plants in the Democratic Republic of the Congo in recent years.

Using a semi-automatic ball mill crushing circuit to crush and grind copper-cobalt ore

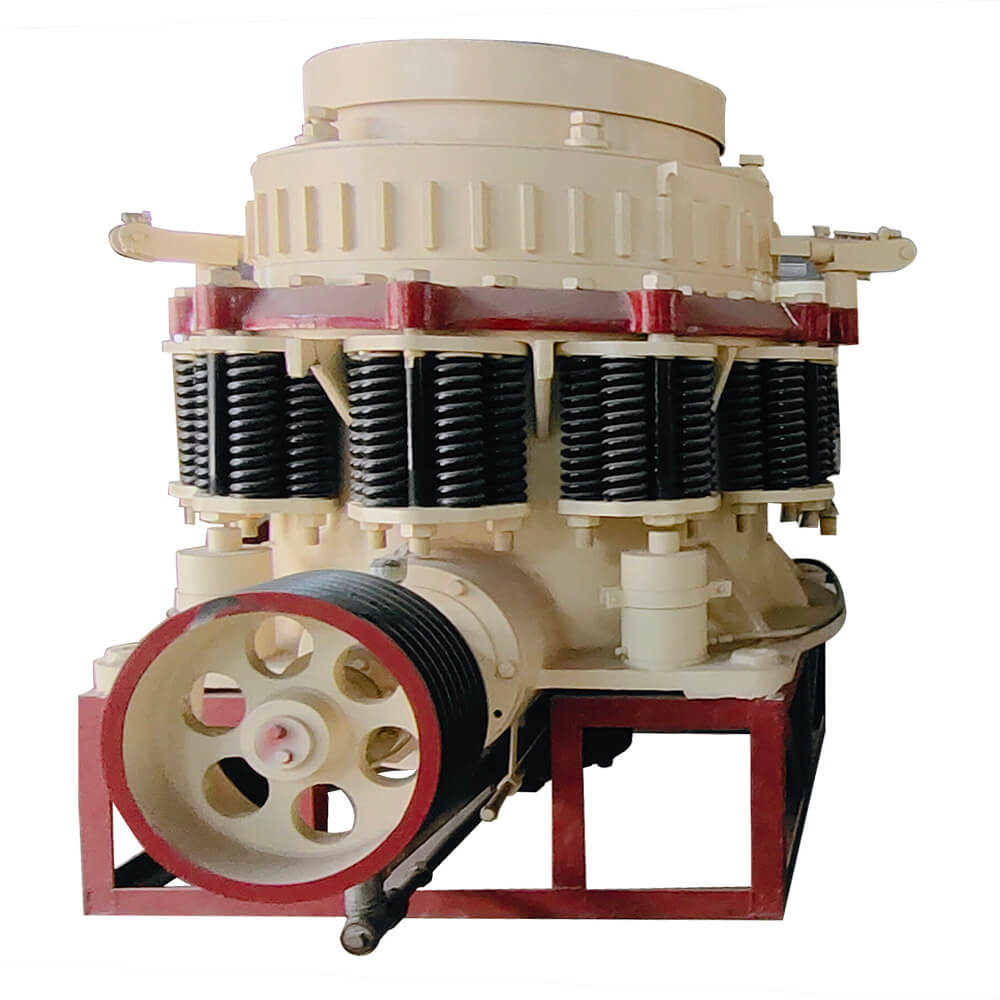

Crusher: jaw crusher, cone crusher

Semi-autogenous mill: ball mill

Advantage:

- Coarse crushing only requires one stage, which minimizes the crushing stage. The process is shorter and requires less equipment. It means less equipment clogging.

- With less equipment, the cobalt processing plant occupies a smaller area, reducing land acquisition costs.

- Simple operation, fewer workers, and reduced labor costs.

Currently, this crushing process is widely used in the new cobalt concentrator in the Democratic Republic of the Congo.

Cobalt mines in the Democratic Republic of the Congo vary greatly in carbon content, mud content, oxidation rate, copper and cobalt grade, and main gangue composition. Rational development and utilization of copper and cobalt mineral resources and improving metal recovery rate require continuous improvement of mineral processing technology. Typical separation processes used in recent large-scale mining projects include the following.

1. Oxygen single flotation before sulfur

Flotation equipment: flotation machine

Concentration equipment: High-efficiency concentrator

Flotation agent: sodium silicate, sodium hydrosulfide, double xanthate, five xanthate, foaming agent

2. Two carbon-oxygen before flotation sulfur-magnetic separation at the tail of flotation

Desliming equipment: double spiral washing machine or drum washing machine

Flotation equipment: flotation machine

Magnetic separation equipment: magnetic separator

Concentration equipment: high-efficiency concentrator

Flotation reagents: Flotation reagents for sulfide ores include MIBC, NaHS, and xanthate; reagents for treating oxidized ores and mixed ores include MIBC, NaHS, ammonium sulfate, ethionine, amyl xanthate, CMC, etc.

3. Sulfur-tail magnetic separation of copper sulfide coarse concentrate before floating oxygen regrinding and cleaning

Flotation equipment: flotation machine

Magnetic separation equipment: magnetic separator

Concentration equipment: high-efficiency concentrator

Flotation reagents: sodium hexametaphosphate, sodium hydrosulfide, butyl xanthate, pentaxanthate, foaming agent.

The obtained copper-cobalt sulfide concentrate and copper-cobalt oxide concentrate are further refined through corresponding methods.

JXSC is a well-known manufacturer and supplier of mining equipment and mineral processing solutions, including equipment and services related to cobalt processing. JXSC primarily provides comprehensive solutions for mining and mineral processing operations, which may include cobalt processing as part of their broader services.

Please visit the official website or contact us for detailed and up-to-date information about JXSC’s cobalt processing solutions. The website should provide information on the equipment, technologies, and services related to cobalt processing and any case studies or projects they have been involved in. Additionally, you can contact our customer support or sales teams for specific inquiries about our cobalt processing capabilities and equipment.