The vast majority of manganese ores in China belong to lean ores, which must be beneficiated. However, most manganese ores are fine-grained, and there are a considerable number of high phosphorus ores, high iron ores, and CO (associated) beneficial metals, which brings great difficulty to beneficiation and processing. At present, the commonly used beneficiation methods of manganese ore are mechanical beneficiation (including ore washing, screening, gravity separation, high-intensity magnetic separation and flotation), fire enrichment, chemical beneficiation, etc.

Manganese Ore Washing and Screening

Ore washing is the separation of ore and mud by hydraulic washing or additional mechanical scrubbing. Common equipment includes an ore washing screen, cylindrical ore washing machine, and trough ore washing machine.

Ore washing operation is often accompanied by screening, such as washing directly on the vibrating screen or sending the ore sand (clean ore) obtained by the ore washing machine to the vibrating screen for screening. Screening can be used as an independent operation to separate products with different particle sizes and grades for different purposes.

Manganese Gravity Separation

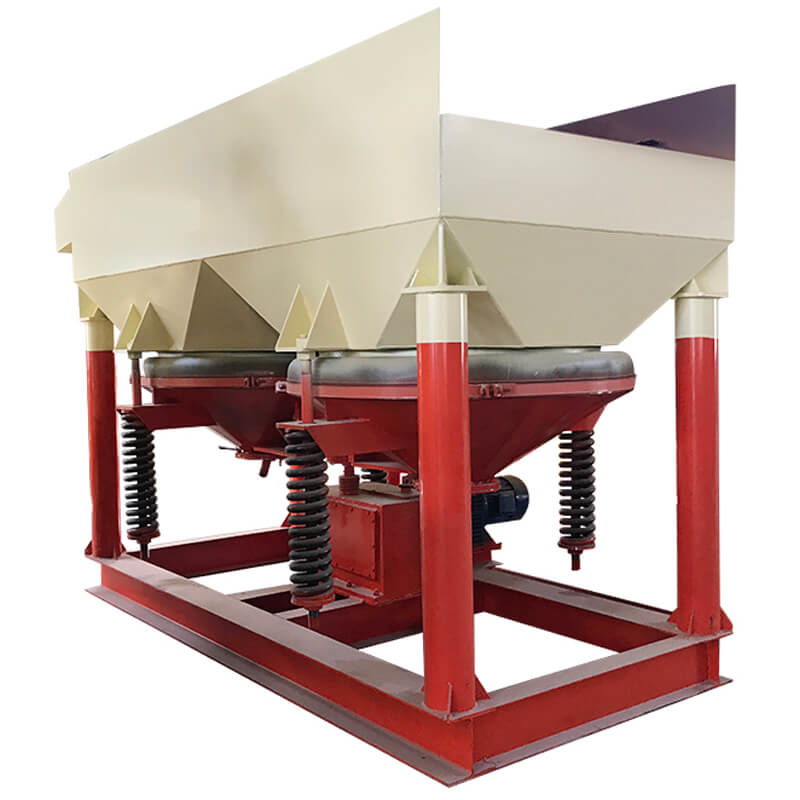

At present, gravity separation is only used to separate manganese ores with simple structure and coarse embedded particle size, especially for manganese oxide ores with high density. Common methods include heavy medium beneficiation, jigging beneficiation, and shaking table beneficiation.

At present, the process flow of manganese oxide ore treatment in China is generally to crush the ore to 6 ~ 0mm or 10 ~ 0mm, and then group it, jigging for coarse grade and shaking tables for a fine grade. The equipment is mostly Hartz reciprocating jig and 6-s shaking table.

High Intensity Magnetic Separation

Manganese minerals are weakly magnetic minerals [specific magnetic coefficient X = 10 × 10-6~600 × 10-6cm3 / g] can be recovered in the high magnetic field magnetic separator with magnetic field strength ho = 800 ~ 1600kA / M (10000 ~ 20000oe), which can generally increase the manganese grade by 4% ~ 10%.

Due to the simple operation, easy control, and strong adaptability of magnetic separation, it can be used for the separation of various manganese ores. In recent years, it has occupied a dominant position in manganese ore dressing. Various new types of coarse, medium, and fine-grained strong magnetic machines have been successfully developed. At present, the most common application of manganese ore in China is the medium particle high-intensity magnetic separator, the coarse and fine particle high-intensity magnetic separators are also gradually applied, and the fine particle high-intensity magnetic separator is still in the experimental stage.

Gravity Magnetic Separation

At present, the newly built and reconstructed gravity magnetic separation plants in China include Liancheng, Fujian, Longtou, Jingxi, and Xialei manganese mines in Guangxi. For example, the Liancheng Manganese Mine gravity magnetic separation plant mainly processes leaching manganese oxide ore, and uses am-30 jig to treat 30 ~ 3mm washed ore, which can obtain high-quality manganese concentrate containing more than 40% manganese. After manual separation and impurity removal, it can be used as the raw material of battery manganese powder. After the jigging tailings and the cleaned ore diameter of less than 3mm are grinded to less than 1m, they are separated with a strong magnetic separator. The manganese concentrate grade should be increased by 24% ~ 25% to 36% ~ 40%.

Strong Magnetic - Flotation

At present, Zunyi Manganese ore is the only one adopting a strong magnetic flotation process. The ore is low manganese, low phosphorus, and high iron manganese ore mainly composed of manganese carbonate ore.

According to the industrial test, the grinding process adopts the rod grinding ball milling stage, and the equipment scale is φ 2100mm × 3000mm wet mill. A strong magnetic separator is used for strong magnetic separation, and CHF inflatable flotation machine is mainly used for flotation machine. After years of production tests, it has good performance and is very suitable for Zunyi Manganese beneficiation application. The successful test of the strong magnetic flotation process and its application in production indicate that the deep separation of manganese ore in China has taken a big step forward.

Fire Enrichment

Pyrometallurgical enrichment of manganese ore is a kind of separation method to deal with poor manganese ore with high phosphorus and high iron, which is generally called the rich manganese slag method. Its essence is a high-temperature separation method that uses the different reduction temperatures of manganese, phosphorus and iron to control their temperature in a blast furnace or electric furnace for selective separation of manganese, phosphorus, and iron.

In 1959, Hunan Shaoyang Zijiang ironworks carried out experiments on a 9.4m3 small blast furnace and obtained preliminary results. Subsequently, in 1962, the Shanghai ferroalloy plant and Shijingshan iron and steel plant smelted manganese-rich slag in blast furnaces respectively. In 1975, the Hunan Manaoshan manganese mine blast furnace not only smelted manganese-rich slag, but also recovered lead, silver, and pig iron (commonly known as semi-steel) at the bottom of the furnace, providing a basis for comprehensive utilization. After entering the 1980s, the production of manganese-rich slag has developed rapidly, and the production of manganese-rich slag has been developed in Hunan, Hubei, Guangdong, Guangxi, Jiangxi, Liaoning, Jilin, and other places.

The pyrometallurgical enrichment process is simple and stable. It can effectively separate iron and phosphorus from the ore, and obtain rich manganese, low iron, and low phosphorus-rich manganese slag. This rich manganese slag generally contains 35% ~ 45% mn35% Mn / Fe? 12 ~ 38, P / Mn < 0.002. It is a high-quality manganese alloy raw material. At the same time, it is also an artificial rich ore which is difficult for general natural rich manganese ore to meet the above three indexes at the same time. Therefore, pyrometallurgical enrichment is a promising beneficiation method for the difficult beneficiation of high phosphorus, high iron, and low manganese in China.

Chemical Manganese Separation

There is a lot of chemical beneficiation of manganese. A lot of research work has been done in China, among which there are many tests. The more promising ones are the dithionite method, black manganese ore method, and bacterial manganese leaching method. At present, it has not been put into industrial production.

Manganese ore powder block

The briquetting method includes three processes: sintering, pelletizing, and briquetting. At present, the sintering method is widely used in China. Only when the manganese concentrate or fine ore is very fine, the -200 mesh is more than 80% and the product is not allowed to contain residual carbon, pelletizing or briquetting is used.

In the early 1950s, sintering pot sintering and indigenous sintering were mostly used for manganese ore powder in China. With the development of iron and steel production, indigenous sintering can not meet the requirements, so they have started to build sintering machines or other high-efficiency block-making equipment. In 1970, China’s first fine manganese ore sintering machine (18m2) was completed and put into operation in Xiangtan Manganese Mine. In 1972, Jiangxi Xinyu Iron and steel plant built two 24m2 sintering machines. In 1977, China’s first manganese concentrate pelletizing equipment 80m2 belt roaster was completed and put into operation in Zunyi Manganese Mine. In the 1980s, Xiangtan Manganese Mine, Bayi manganese mine, and Xiangxiang ferroalloy plant successively built more than 18 ~ 24m2 sintering machines, and Shanghai ferroalloy plant introduced pelletizing equipment as powder ore block.

The development of block-making technology has brought greater economic benefits to the smelting of manganese alloys. Taking Xinyu Iron and steel plant in Jiangxi Province as an example, the technical indexes of blast furnace smelting can be greatly improved by increasing the clinker ratio and replacing hot sinter with cold sinter.

Manganese ore smelting

Manganese ores, manganese alloys, and other products are mainly known as high carbon and low carbon manganese.

High carbon ferromanganese

Blast furnace production is mainly used in China. In the 1950s, there was no special manufacturer to produce blast furnace ferromanganese (high carbon ferromanganese), but some iron and steel plants made and sold their own products, and the production volume was very small. Since 1958, Xiangtan Manganese Mine has successively built 6.5m3 and 33m3 blast furnaces for smelting ferromanganese. After the 1960s, Xinyu, Yangquan, No. 3 plant of Maanshan Iron and Steel Co., Ltd., and No. 4 plant of Chongqing Iron and Steel Co., Ltd. switched to production of blast furnace ferromanganese. In the 1980s, blast furnace ferromanganese developed faster. The output of blast furnace ferromanganese increased from 200000 tons in 1981 to 400000 tons in 1995.

The products produced by electric furnaces include carbon ferromanganese, medium and low carbon ferromanganese, manganese silicon alloy, and metal manganese. Jilin Ferroalloy Factory was the first one to produce an electric furnace in China. It was completed and put into operation in 1956, and the maximum electric furnace capacity is 12500kVA; In the early 1960s, Hunan, Zunyi, Shanghai, and other ferroalloy plants were successfully completed and put into operation. These plants can produce carbon ferromanganese, medium, and low carbon ferromanganese, and manganese silicon alloys; Zunyi ferroalloy plant also uses electro silicothermic method to produce metal manganese. According to the records of the Ministry of metallurgical industry in the main technical and economic indicators of ferroalloys in China in 1995, 11 of the 15 key ferroalloy plants in China produced manganese alloy products in 1994. These key ferroalloy plants have made important contributions to the production of the iron and steel industry through continuous development and expansion.

Since the 1980s, local small and medium-sized ferroalloy enterprises have developed rapidly. According to statistics, the proportion of ferroalloy output of local small and medium-sized enterprises in the country increased from 32.39% in 1980 to 54.01% in 1989, and reached 69.85% in 1996. The number of enterprises has reached more than 1000. Most of these small and medium-sized enterprises use 1800kVA small electric furnaces with backward equipment and poor product quality.

The equipment used in the production of ferromanganese and manganese silicon alloy in an electric furnace is basically the same. A submerged arc furnace is adopted, and the capacity of electric furnace transformer is generally 1800 ~ 12500kVA. Hunan and Zunyi ferroalloy plants have imported 3000kva and 31500kVA manganese silicon electric furnaces from Germany and have been put into operation.

The flux process is generally used in the production of high carbon ferromanganese in an electric furnace in China. The production of manganese silicon alloy generally adopts the slag process.

The production of medium and low carbon ferromanganese mainly includes the electric furnace method, oxygen blowing method, and shaking ladle method. The shaking ladle method includes the direct production of medium and low carbon ferromanganese in shaking ladle and the production of medium and low carbon ferromanganese by shaking ladle electric furnace method. The ladle shaking electric furnace method has advanced technology, stable production, and good technical and economic effect. At present, this method is adopted in ferroalloy plants such as Shanghai and Zunyi.

The production methods of metallic manganese include pyrometallurgy and hydrometallurgy. Pyrometallurgical smelting of metallic manganese began in 1959 in China. Zunyi ferroalloy factory successfully produced manganese by electro silicothermic method for the first time and has been producing manganese exclusively until now. The production process adopts three steps. The first step is to refine manganese ore into manganese-rich slag; In the second step, manganese-rich slag is used to refine high silicon manganese alloy. In the third step, manganese-rich slag is used as raw material, high silicon manganese is used as a reducing agent and lime is used as a flux, that is, electro silicothermic method to produce metal manganese. Hydrometallurgy is mainly an electrolytic process, often called electrolytic manganese. China built the first electrolytic manganese production plant from Shanghai 901 plant in 1956. By the early 1990s, there were more than 50 large and small electrolytic metal manganese plants, with an annual total production capacity of more than 40000 tons. The production process is roughly divided into three production processes: preparation of manganese sulfate solution, electrolysis, and post-treatment. Post-treatment is a series of operations after electrolysis, including product purification, water washing, drying, stripping, packaging, etc. Finally, qualified electrolytic manganese products are obtained, containing 99.70% ~ 99.95% mn99.

JXSC supplies manganese ore process plant and equipment to help you solute mineral ores beneficiation.