Original Lead-zinc Ore Concentrator Project Overview

Establishment time: Put into operation in the 1970s

Problem

- Worn out equipment

- The equipment failure rate is high

- Too many devices and low efficiency

- High production cost

- Low production index

- Serious environmental pollution and other issues.

To solve the above problems, achieve the purpose of expanding production capacity, improving the technical and economic indicators of the enterprise, improving the level of safety and environmental protection, and realizing the aim of saving energy and reducing consumption. It is necessary to carry out a technical transformation of the lead-zinc dressing plant.

Lead-zinc Ore Dressing Plant Improvement

Ore information: The ore in the concentrator is mainly lead, zinc, and silver. The main metal minerals are galena, sphalerite, chalcopyrite, pyrrhotite, cassiterite, argentite, white lead ore, etc.; The main gangue minerals are quartz, screen stone, and carbonate minerals, followed by feldspar and argillaceous hornblende.

Embedding Granularity: 0.1 mm ~0.05mm or finer

Capacity: Expand from 250t/d to 500t/d

Requirements

- Use advanced and reliable process flow and equipment to improve mineral processing products’ technical and economic indicators.

- Combined with the actual situation of the enterprise, try to use the existing equipment and facilities to save investment.

- The selection of newly added equipment meets the requirements of advanced, reliable, efficient, and energy-saving, to achieve energy saving and consumption reduction.

- The technological process is reasonable and has a certain degree of flexibility. The equipment configuration is as far as possible in the existing plant and facilities to realize the self-flow of ore pulp as much as possible.

- No or little impact on production during the process of technological transformation, the effective connection between output and technological transformation.

- The technological transformation of the enterprise has good economic benefits, achieves the goals of advanced mineral processing indicators, low production costs, energy conservation, and emission reduction, and reaches the equipment level of similar enterprises.

Equipment Update

1. Crushing equipment

Coarse crushing: The original PE400x600 jaw crusher is still used.

Fine crushing: A double-cavity laminated crusher PX900 is selected as the fine crushing equipment.

The double-cavity lamination crusher is a new type of high-efficiency fine-crushing equipment innovatively developed by combining the improved and upgraded double-cavity gyratory crusher with the advanced lamination crushing principle.

Working principle of double cavity lamination crusher

The double-cavity laminated crusher relies on a high-wear-resistant crushing plate for crushing work, which forms a double-crushing chamber with symmetrically arranged curved crushing plates. The broken silver is installed on the eccentric position of the main shaft through the bearing, and the motor drives the main shaft to rotate. Due to the eccentric effect, the broken spokes perform the high-speed rotary motion. The generated cyclic progressive extrusion force continuously crushes the high-density multi-layer materials in the two crushing chambers. It fully exerts the functions of laminated and secondary crushing to obtain a very high crushing rate.

The double-chamber laminated crusher is suitable for crushing any hard ore, processing fine-grained products with high output, achieving low steel consumption and low-cost operation, and the equipment runs smoothly and is easy to maintain.

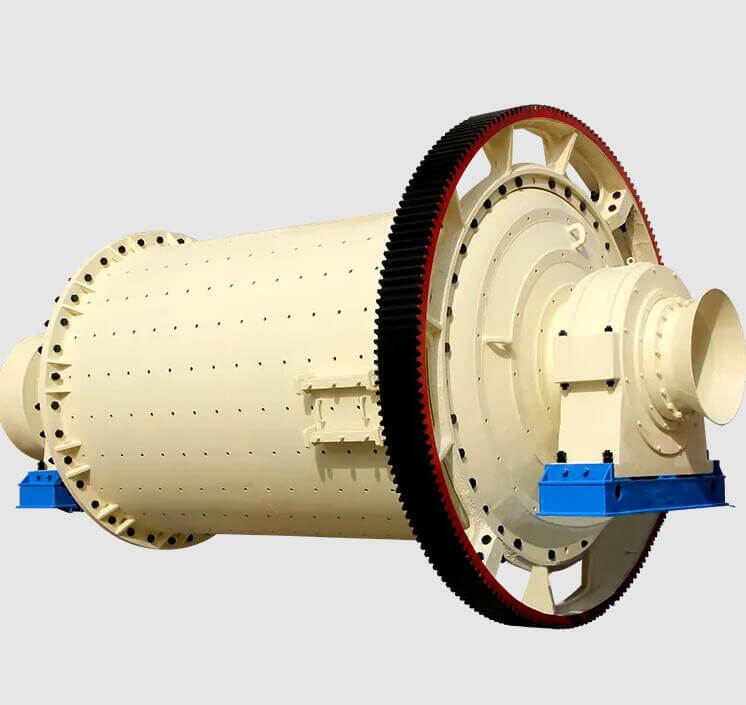

2. Grinding and grading equipment

Considering the flexibility of the system and less impact on production during the expansion process, the grinding process is a double-series one-stage closed-circuit grinding. Both series are closed-circuited by ball mills and spiral classifiers. The overflow fineness is -0.074mm, accounting for 65%.

Series (original): 1 set of MQG1500 x 3000 ball mill and 1 set of G-12 spiral classifier.

Series I (new): 1 set of MQG2100 x 3000 ball mill and 1 set of FG-15 spiral classifier.

3. Flotation equipment

At present, the lead-zinc dressing plant uses 5A and 1A flotation machines. Due to the flotation machines’ long history, equipment operation’s high failure rate, and the poor separation index, we replace all the flotation machines with BF flotation machines. BF-2.8 flotation machines are used for priority flotation roughing and sweeping operations and zinc roughing and sweeping operations. The rest of the flotation machines are all BF-1.2 flotation machines.

The BF-type flotation machine is a mechanical agitation with self-suction and self-suction slurry. Its impeller is composed of closed ratio double truncated cones, which can generate powerful slurry circulation.

BF Flotation Machine Features

- Large suction volume and low power consumption.

- Each tank has triple the functions of air suction, slurry suction, and flotation. It forms a flotation circuit without any auxiliary equipment. It is arranged horizontally and is convenient for process changes.

- Reasonable pulp circulation can minimize coarse sand precipitation.

- It is equipped with automatic control and electric control device for the slurry level, which is easy to adjust.

4. Dust removal equipment

Dust removal has always been the weak link of the enterprise. We select the KDLL pulse filter cartridge dust collector for this lead-zinc dressing plant improvement.

The pulse dust collector is a new type of filter dust removal device, which has the advantages of high purification efficiency, small size, large filtration area, good filtration effect, slight pressure loss, the long service life of the filter cartridge, quick and convenient installation and maintenance, continuous use, etc. This dust removal design has successful experience in the industry, advanced low-resistance, constant-velocity, and large-flow pipe network technology, the best practical technology for hood switching valves, and dust collection and discharge have reached environmental protection indicators.