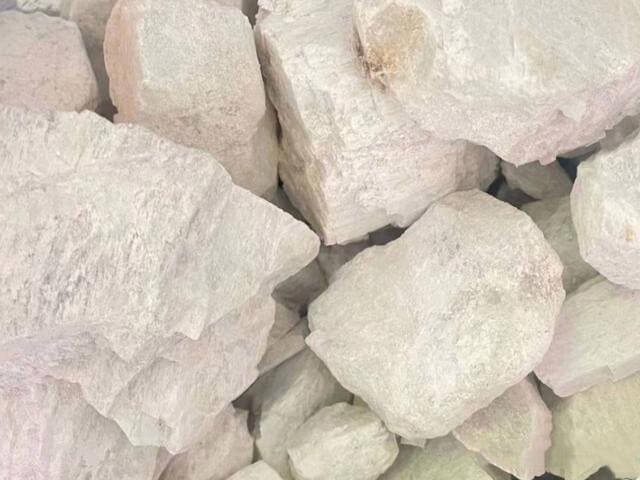

Developing renewable energy technologies is becoming increasingly important as global energy demand grows. Spodumene, a critical raw material widely used in lithium-ion batteries, has become a driver of renewable energy. However, as the request for this high-value resource continues to increase, it is critical to find and develop methods for recycling spodumene to ensure its continued supply and reduce over-reliance on natural resources.

The Importance of Spodumene

Spodumene is a mineral of significant importance in various industries due to its unique properties and applications. Here are some of the critical reasons why spodumene is essential:

- Primary Source of Lithium: Spodumene is the primary source of lithium, a critical element in modern technology. Lithium-ion batteries, widely used in electric vehicles, smartphones, laptops, and renewable energy storage, rely on lithium extracted from spodumene. As the demand for electric cars and renewable energy grows, spodumene becomes increasingly important for global energy storage solutions.

- Energy Storage Revolution: The rise of electric vehicles and renewable energy sources like solar and wind power has created a surge in demand for lithium batteries. Spodumene is a critical raw material for producing high-quality lithium compounds, such as lithium carbonate and lithium hydroxide, essential components in these batteries. Storing energy efficiently is vital for reducing greenhouse gas emissions and transitioning to a more sustainable energy future.

- Green Energy Transition: Spodumene is vital in transitioning to a cleaner and more sustainable energy system. As the world shifts away from fossil fuels, lithium-ion batteries enable renewable energy storage, ensuring a stable power supply even when the sun isn’t shining or the wind isn’t blowing. Spodumene mining and lithium production are essential for reducing carbon emissions and mitigating climate change.

- Electric Mobility: The automotive industry is increasingly adopting electric vehicles (EVs) to reduce emissions and dependence on fossil fuels. Spodumene-derived lithium batteries power these EVs, making spodumene a key component of the automotive sector’s sustainability efforts. The growth of EVs also has economic implications, with potential job creation in spodumene mining and battery manufacturing.

- Technological Advancements: Apart from lithium-ion batteries, spodumene is also used in various other advanced technologies. For example, it is employed in producing ceramics, glass, and specialty glass products, as it enhances the transparency and durability of these materials. Additionally, spodumene is utilized in manufacturing aluminum and as a flux in steel production.

- Economic Impact: Spodumene mining can have a significant economic impact on regions where it is extracted. It creates jobs, generates revenue for local communities, and contributes to regional development. The economic benefits extend beyond the mining phase, as downstream industries like battery manufacturing and technology development can thrive when a stable spodumene supply is available.

- Research and Development: Spodumene research is ongoing to improve the efficiency and sustainability of lithium extraction processes. Developing new methods to extract lithium from spodumene more efficiently and with minimal environmental impact is crucial to ensure a sustainable supply chain.

Spodumene is a lithium aluminum silicate mineral found widely in rocks and ores on Earth. It is one of the primary raw materials for lithium-ion batteries, which are core components in mobile devices, electric vehicles, and energy storage systems. With the popularity of electric cars and renewable energy development, the demand for spodumene has increased rapidly. Therefore, we must find efficient ways to recycle spodumene to meet future energy needs.

Traditional Mining and Problems

Currently, spodumene is mainly obtained through traditional mining methods involving mining, ore refining, and energy-intensive production processes. This causes serious damage to the natural environment and wastes a lot of energy resources. In addition, traditional mining methods are also limited by limited mineral resources and uneven geographical distribution.

Innovative Spodumene Recycling Methods

In order to solve the above problems, scientists and engineers have been working hard to develop new spodumene recycling methods. Here are some innovative approaches that promise to improve spodumene recycling:

- Recycling from used batteries: Used lithium-ion batteries can serve as a valuable lithium resource bank. Recycling the spodumene in these batteries could reduce the need for new mining.

- Improve mining efficiency: Innovative mining technologies, such as machine learning and automation, can increase the efficiency of spodumene mining and reduce the impact on the natural environment.

- Lithium extraction from seawater: Seawater contains a large amount of lithium. Although the concentration is low, the technology is gradually maturing, and the demand can be met by extracting lithium.

- Lithium recycling: Designing more sustainable batteries so that the spodumene within them can be more easily recycled at the end of their life.

- Hydrometallurgical Processes: Researchers are investigating hydrometallurgical methods, such as leaching and solvent extraction, to recover lithium from used batteries and spodumene-containing waste materials. These methods involve dissolving lithium compounds from the spodumene material and precipitating them as high-purity lithium carbonate or lithium hydroxide.

- Biotechnological Methods: Some innovative approaches involve using bacteria or microorganisms to extract lithium from spodumene ores selectively. This bioleaching method can be environmentally friendly and potentially more cost-effective than traditional chemical processes.

- Advanced Separation Techniques: Researchers are exploring advanced separation techniques like membrane filtration and ion exchange to extract lithium from spodumene-bearing materials selectively. These methods can offer high selectivity and purity.

- Electrochemical Recycling: Electrochemical processes are being developed to recover lithium from used batteries and other lithium-containing materials. These methods can be energy-efficient and potentially yield high-purity lithium compounds.

Environmental Protection And Sustainability

Innovative methods of spodumene recycling not only reduce reliance on natural resources but also reduce environmental impact. These methods help reduce mining pollution of soil and water resources, greenhouse gas emissions, and energy consumption in production. This aligns with global sustainable development goals and contributes to the clean energy transition.

Continuing innovation in spodumene recovery methods is an area that is both challenging and promising. With the rapid development of renewable energy, the demand for spodumene will continue to grow. Therefore, we must take action to promote the development and application of more environmentally friendly and sustainable spodumene recycling methods. Not only will this help ensure the sustainability of future energy supplies, but it will also help reduce negative environmental impacts and move us towards a greener, more sustainable future.