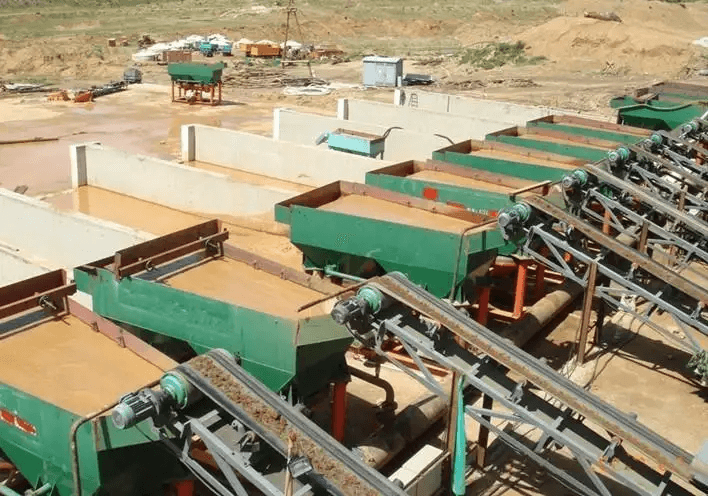

The primary wastewater process of the gold ore concentrator is through the steps of pressure filtration of fine tailings, dust removal, ore washing, cooling, flushing, and drainage. The process is complex, the discharge is too large, and it contains many heavy metal ions, solid suspended matter, and many more. However, the harmful components of gold mine wastewater treated by full flotation technology have been reduced. However, to realize the clean production of the concentrator, it is also necessary to introduce recycling wastewater treatment technology, which not only reduces the impact of discharged wastewater on nature but also makes new use of backwater, thereby reducing the amount of fresh water and tailings ponds burden.

Two Common Methods for Treating Gold Ore Beneficiation Wastewater

There are two standard methods for treating gold beneficiation wastewater in traditional gold mines.

1. Full flotation process

Through the interaction of various chemical agents and tailing minerals, use the difference in chemical properties of the surface between ores to separate the minerals effectively.

2. The whole mud cyanidation leaching process

Finely grind the gold ore to make a pulp, and then the ore is recovered through secondary treatment such as cyanide leaching and activated carbon adsorption.

The above two methods are very beneficial to the output of gold ore, but the pollution in the wastewater discharge is relatively large.

Treatment Methods and Improvements of Gold Mine Wastewater Pollutants

Various Wastewater Treatment Methods in The Concentrator

Treatment of wastewater containing suspended solids

1. Natural precipitation

Wastewater containing suspended solids in mineral processing plants includes tailings, wet dust collection, and surface water for washing. Tailings water is generally used for the sedimentation of tailings ponds. Wet dust collection and surface flushing water enter sedimentation or thickening tanks for sedimentation. After some time, it will separate the solid and liquid. And the separated supernatant is reused for production or directly discharged.

2. Dosing chemical precipitation

The tailings water contains water glass and oleic acid, and the ore particle size is too fine during the grinding process, so the fine tailings are suspended in the water and cannot be clarified for a long time. Therefore, adding chemical agents such as No. 3 flocculant or lime is necessary to obtain a better clarification effect. Finally, the input amount of lime in the plant is about 0.3%~0.5% of the pulp amount.

Treatment of cyanide-containing wastewater

Improvement of Gold Mineral Processing Wastewater Treatment Method

According to the introduction of the above method, the current treatment methods of gold mine wastewater are mostly based on natural purification. Then a large-scale treatment is carried out with various chemical agents, and further treatment is carried out. For the treatment of cyanide-containing wastewater, in the whole treatment process, chemical precipitation is used as the core method, and electrolysis is used as an alternative link. In the precipitation process of the branch, three commonly used coagulants, such as ferrous sulfate, poly ferric sulfate, and polyaluminum sulfate, were analyzed and compared, and the final result was that the treatment effect of ferrous sulfate was better.

After further adjustment and improvement of the experiment, we found that:

- Natural purification has no room for improvement and operation in the overall gold mine wastewater treatment.

- The electrolysis link is one of the essential methods to ensure wastewater discharge in the subsequent production of ores.

- Chemical precipitation is the perfect link in the whole wastewater treatment.

- The cost of the ion exchange method in the mine treatment is relatively high, which makes the ozonation of the overall wastewater pool more complex. It needs to implement the degree of ozonation well. And it is unlikely to be effective for iron compounds and ferricyanide. Compounds are efficiently chemically broken down to extract some native metals that can be recycled and reused.

In the three test schemes, we use three coagulants alone, add coagulants to three different coagulants, and use two different methods to measure the removal rate of the dichromate obtained. We obtained the overall tendency to decline. The removal rate of adding coagulant aid is higher than that of using coagulant alone.

Recycling of Gold Mine Wastewater

Wastewater reuse is the simplest and most effective method in polymetallic mineral processing wastewater treatment. The test shows that the circulating water treated by the recycling method can continue to be used without affecting the beneficiation index of the mine at all, the closed cycle of the beneficiation wastewater is realized, and the environmental benefits of no pollution and zero discharge are realized.

Through consulting the data, it can find that the sewage treatment of many common mineral mines has reached the discharge standard of our country and can be discharged or reused. Still, the value and effect of secondary or multiple utilization could be more obvious. However, the rare mineral gold mine is different from common minerals. It detects a high content of recoverable gold in the wastewater discharged to the outside so it can reuse for sewage recycling. There are more than three or even more than six application examples. Combined with sewage purification treatment and reuse for some gold mines, it will bring good economic benefits and value to the enterprise.

Summarize

- When treating wastewater from mineral processing plants, tailings ponds should generally be fully used for clarification and natural purification. If it can’t meet the discharge requirements, add flocculants, chemicals, or other treatment methods. When using chemical agents, try to use one agent.

- The chemical agents used should be those with low toxicity, non-toxicity, high efficiency, or less pollution, and at a reasonable price. Lime is the most common agent used to treat mineral processing plant wastewater.

- Analyze the composition of the wastewater and recycle the wastewater. It ensures regular production operation and reduces the enterprise’s beneficiation cost.