When treating mine wastewater, the staff needs to pre-treat it. That is, filter and separate the large particulate matter in the mine wastewater and purify the mine wastewater in the first step. The resulting mine wastewater is in Proceed to the next step. So do you know what methods there are?

The Source of Mineral Processing Wastewater

Generally speaking, all external drainage in the production process of the mineral processing plant is collectively referred to as mineral processing wastewater, specifically including

- Mine washing wastewater: contains a large amount of fine-grained slime and a small number of ore particles;

- Wastewater from the crushing system: mainly contains ore particles, which can be reused after sedimentation;

- Equipment cooling water: including the cooling water of the crusher, the ball mill, and the water sealing water of the vacuum pump, the water volume is small, and the pollutants are mainly oily substances, which can recycle after treatment;

- Gravity and magnetic separation wastewater: mainly contains mineral particles and suspended solids, which can be basically reused after clarification;

- Flotation wastewater: mainly from the overflow water and tailings pond overflow water produced after concentrate and tailings pass through the two-stage dewatering process of thickening and filtration and contain flotation reagents and a small number of suspended solids;

- Flushing wastewater: the ground flushing water of each workshop;

- Others: “running, running, dripping, and leaking” in the beneficiation process and the drainage of the accident pool.

Mine Wastewater Treatment Method

(1) Acid-base neutralization method

Usually, mine wastewater contains a large number of acidic pollutants and heavy metal substances, which is the reason why mine wastewater is often acidic. The staff can use this property of mine wastewater to conduct acid-base neutralization treatment, add certain alkaline substances to the mine wastewater to make it neutralize, increase the PH value of the mine wastewater, and make it neutral. Workers often choose common alkaline neutralizers such as sodium hydroxide and calcium hydroxide for the reaction in practical applications. The acid-base neutralization method is relatively simple compared to other mine wastewater treatment methods. And the price of the alkaline neutralizer is relatively low. It does not need to consume a lot of human and material resources, and the scope of application in practical applications is wide.

(2) Vulcanization method

When dealing with mine wastewater, some workers will use the sulfidation method for treatment. When using the vulcanization method for treatment, it is often necessary to put the vulcanizing agent into the mine wastewater to fully react and remove the metal ions in the mine wastewater by precipitation and filtration to obtain relatively clean mine wastewater. For the sulfidation method, its application range is fairly wide, and there is no strict requirement on the PH value of mine wastewater. In addition, since the pollutants produced using the sulfidation method are solid, the post-treatment process is relatively simpler, and the removal efficiency is relatively high. However, since hydrogen sulfide is harmful to the human body and is often generated when a vulcanizing agent is used, the sulfidation method is generally not used for post-treatment of mine wastewater when necessary.

(3) Extraction electrowinning method

Extractive electrowinning can also be used in the treatment of mine wastewater. This method is based on the difference in solubility of different solutes in the extraction agent from mine wastewater. Generally speaking, substances with higher solubility in the extraction agent have a relatively long efflux time. In comparison, those with lower solubility in the extraction agent have a longer elution time. The outflow time is relatively short of removing the impurities in the mine wastewater and preliminarily treating the mine wastewater. It can say that the extraction electrowinning method can effectively remove heavy metal substances in mine wastewater. This method has relatively high efficiency, simple equipment, and low technical requirements for operators. However, this method has a specific selectivity and only has a high extraction efficiency for substances with a relatively small content of heavy metals.

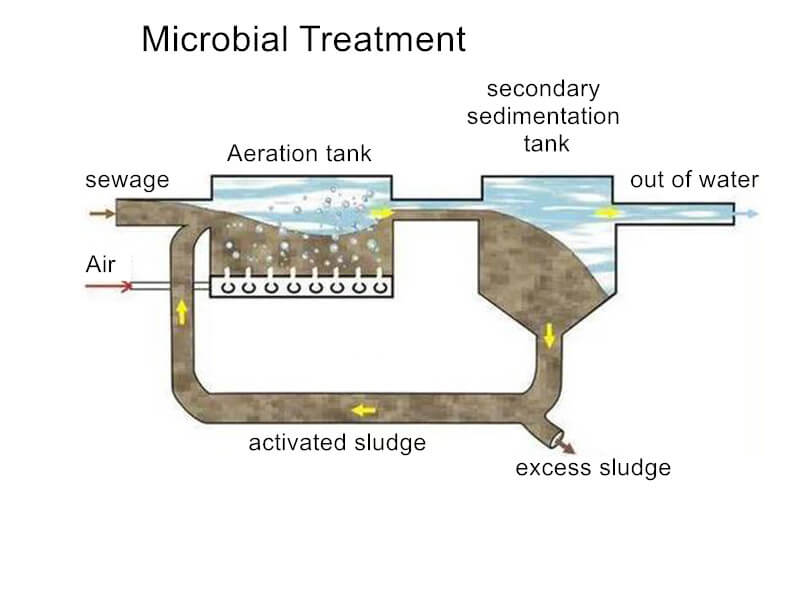

(4) Microbial method

Compared with other mine wastewater treatment methods, the microbial process has a relatively lower cost and a more comprehensive application range. It can effectively treat heavy metals or other polluting substances in mine wastewater. Currently, bacteria are used as treatment agents when using the microbial method to treat mine wastewater. The characteristics of bacteria themselves are used to adsorb or transfer the pollutants in the wastewater to realize the effective treatment of mine wastewater. At present, the microbial treatment of mine wastewater has attracted the attention of many experts and scholars.

(5) Reverse osmosis method

Since the last century, reverse osmosis has been rapidly developed in the desalination of water, and it seems to have great potential for the application of sewage treatment. A single reverse osmosis stage can remove 90% or more salts. Because the channels through the permeable membrane are tiny, microorganisms such as bacteria and viruses can be filtered out of the feedwater. It can also almost remove Granular objects, colored organisms, and living organisms with a high-quality reverse osmosis membrane. The process of reverse osmosis membrane is developing rapidly, and it is estimated that the processing cost can be lower. The main reason for the low disposal cost is the film’s long life, but this is not guaranteed to be the case in all cases. In addition, the treatment of wastewater by reverse osmosis also includes the treatment of concentrates of wastewater by suitable methods since such concentrates account for the majority of the initial wastewater volume and cannot be ignored.

Due to the different properties and sorting methods of various metal and non-metallic minerals, the properties and components of mineral processing wastewater produced by mines are also different. We should select the appropriate wastewater treatment technology and recovery methods according to the properties of wastewater from various sources and the requirements of the beneficiation process on the backwater properties. Improving the recycling rate of mineral processing wastewater and realizing the clean discharge of sewage is the main development direction of my country’s mine development in the future. It is a necessary means for enterprises to achieve sustainable development.