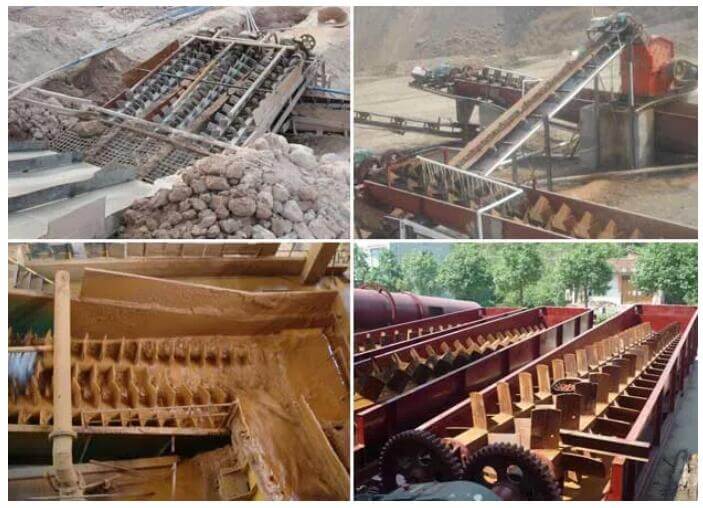

Double Helix Ore Washers are essential in ore processing operations as they help improve the quality of ores by removing contaminants. They find applications in various mining and mineral processing operations where the purification of ores is necessary to meet quality standards and downstream processing requirements. The spiral washing machine is mainly used for washing manganese ore, iron ore, phosphate ore, and other minerals. Double-spiral washing machine equipment is used for cleaning and separating sludge and stains from manganese ore, iron ore, and other low-grade minerals. It has a large processing capacity, is easy to install, is simple to operate, and has low cost and high efficiency. The double helix ore washing machine is a large-scale mining equipment used in ferrous and non-ferrous metallurgical mines, steel, metallurgy, chemical industry, and building materials to wash ores and stones. It has a large processing capacity and is suitable for large-scale production of ores; It is an ideal equipment for enterprises that have strict requirements on the cleanliness of stone.

Features

The double helix ore washer has a long spiral body, a good sealing system, a simple structure, strong processing capacity, and easy maintenance. The sand produced has the characteristics of low water content and low mud content. Double spiral washing machine equipment is widely used in various ore mining industries.

Applications

The spiral washer is suitable for desliming operations where a large amount of sand and gravel are used in construction sites, sand and gravel plants, concrete precast plants, and water and electricity construction sites. The spiral washer can also be used to wash, classify, and dehydrate ores. Spiral washers can be used in scrubbers or screening and grading equipment.

Structure and Materials

- It adopts durable and wear-resistant cast iron blades, which are easy to replace after wear.

- Use a heavy-duty spindle.

- Extra-large bearings and gears ensure long equipment life.

Working Principle

The Double Helix Ore Washer’s working principle involves rotating two helical or spiral shafts within a water-filled tank. As the shafts rotate, they agitate the ore and water mixture, allowing the ore particles to separate from impurities and dirt. Clean ore particles are lifted upward along the helical structure, while impurities and dirt are washed away and discharged through an outlet.

Double helix ore washing equipment is washing equipment that performs mechanical classification based on the principle that the specific gravity of solid particles is different and, therefore, the sedimentation speed in the liquid is different. Double spiral washer equipment is suitable for washing, grading, impurity removal, and other operations in metallurgy, building materials, hydropower, and other industries. Double spiral washer equipment is ideal for washing granular and coarse-grained materials. The double-shaft spiral stone washing machine uses the buoyancy of water to separate dust and impurities from the sand. After stirring the spiral blade, the purpose of filtering water, removing impurities, and improving transportation is achieved. During the lifting process, mixing work was also carried out. The double-shaft spiral stone washing machine produces sand to achieve uniform mixing without distinction between fine and coarse sand.

Double Helix Ore Washer Manufacturer

JXSC Mineral is a reputable mining equipment manufacturer, including the Double Helix Ore Washer, renowned for its quality, reliability, and innovation. With years of experience and expertise, we design and produce ore washers that meet the stringent demands of modern mining operations. Our Double Helix Ore Washers feature robust construction, precision engineering, and advanced technology, ensuring efficient ore washing and separation. JXSC Mineral prioritizes customer satisfaction, providing comprehensive support services, including installation assistance, technical guidance, and after-sales support. Their commitment to excellence and continuous improvement has made them a trusted partner for mining companies worldwide seeking high-performance equipment to optimize their ore processing operations.

Double Helix Ore Washer Installation

The installation process for a Double Helix Ore Washer can vary depending on the specific model and manufacturer. However, here are some general steps that are typically involved in installing such equipment:

Site Preparation: Choose an appropriate location for installing the Double Helix Ore Washer. Ensure that the ground is level and stable to support the weight of the equipment.

Foundation: Construct a suitable foundation or platform to support the washer. The foundation should be strong, level, and properly anchored to prevent movement during operation.

Assembly: If the washer comes in separate parts, assemble the components according to the manufacturer’s instructions. This may involve attaching the helical shafts, water tank, motor, and other components.

Positioning: Carefully position the assembled washer onto the prepared foundation. Use lifting equipment or machinery to move and position the equipment safely.

Alignment: Ensure that the washer is properly aligned on the foundation. Use leveling tools to adjust the position of the equipment as needed, ensuring that it is level in all directions.

Connections: Connect the necessary utilities to the washer, including water supply lines, electrical connections, and any other required connections. Follow the manufacturer’s guidelines for the proper installation of these utilities.

Testing: Before operating the washer, perform a thorough inspection to ensure all connections are secure and the equipment is installed correctly. Conduct initial startup tests to check for proper operation and functionality.

Commissioning: Once the installation and testing are complete, commission the washer for operation. Follow the startup procedures outlined in the manufacturer’s manual and make any necessary adjustments as needed.

Training: Train personnel operating the washer on how to use the equipment safely and efficiently. Provide instructions on operating procedures, maintenance tasks, and safety precautions.

Documentation: Keep thorough records of the installation process, including any adjustments made, test results, and training provided. Maintain documentation for future reference and troubleshooting.

Following the manufacturer’s specific instructions and guidelines for installing the Double Helix Ore Washer is essential to ensure proper installation, safe operation, and optimal performance. If you’re unsure about any installation process, consult the manufacturer or a qualified technician for assistance.