Cone crusher plays an essential role in the mining industry. It is a crushing machine suitable for raw materials in metallurgy, construction, road construction, chemical, and silicate industries. So it’s commonly used in mining, smelting, building materials, roads, railways, water conservancy, the chemical industry, and many other sectors. The cone crusher has a large crushing ratio, high efficiency, low energy consumption, and uniform particle size. It is suitable for medium and fine crushing of various ores and rocks. Its structure is simple, easy to maintain, and easy to operate and adjust. There are many models according to the different crushing principles and product particle sizes.

Cone Crusher Types

Spring Cone Crusher

The spring cone crusher is the crushing cavity type of the spring cone crusher. The use of ore determines the crushing cavity type. The standard type is suitable for medium crushing, the medium type is suitable for fine crushing, and the short head type is suitable for ultrafine crushing. It is ideal for crushing hard and medium-hard ores and rocks, such as iron ore, copper ore, limestone, quartz, granite, basalt, diabase, etc. The spring cone crusher is widely used in metallurgy, construction, road construction, and chemical and phosphate industries.

The feed particle size of the spring cone crusher is ≤300mm, and the capacity is 12-700 t/h. The spring cone crusher mainly achieves the purpose of crushing through the rotation and swing of the eccentric sleeve. In such a working state, it has strong stability, fewer wearing parts inside the machine, and the advantage of a longer service life, which can reduce unnecessary maintenance costs. Spring cone crusher is suitable for crushing ores and rocks with medium and above hardness.

Compound(Simmons) Cone Crusher

The composite spring cone crusher adopts the best combination of crushing frequency and eccentricity, which makes the crushed material finer. The crushing capacity is higher than that of similar models, and it also enhances the lamination and crushing effect between material particles.

The feed particle size of the compound cone crusher is ≤314mm, and the capacity is 27-1814 t/h. Compound cone crusher(also known as Simmons cone crusher) includes the standard and short head types. Generally speaking, the standard type is suitable for coarse and medium crushing, and the short head type is ideal for medium and fine crushing, so the compound cone crusher is not suitable for ultra-fine crushing or sand making. It is the most commonly used cone crusher on occasions that do not require high product particle size.

Full Hydraulic(GYS Serial)Cone Crusher

The full hydraulic cone crusher is also called the GYS cone crusher. It combines the performance of the multi-cylinder hydraulic cone crusher according to the actual production needs, introduces high-tech production technology, and incorporates new design concepts. It’s the medium and fine crushing equipment with relatively strong production capacity.

The feed particle size of the full hydraulic cone crusher is ≤314mm, and the capacity is 36-1814 t/h. The hydraulic insurance system of the full hydraulic cone crusher is relatively powerful. When the machine has an iron fault or a stuffy car, the support sleeve and the top of the fixed cone can hydraulically connect to the top of the fixed cone to facilitate the removal of faults. The structure is particularly energy-efficient during operation. The full hydraulic cone crusher is suitable for crushing materials containing foreign matter, and the iron passing function is relatively reliable because of the high degree of automation, convenient operation, and low failure rate.

Multi-cylinder Hydraulic Cone Crusher

The multi-cylinder hydraulic cone crusher combines modern material technology and computer technology. It inherits and develops original and new high-performance crushing equipment based on crushing equipment. With a large crushing force, fast rotation speed, high yield of crushed products, and high content of fine ore, it is ideal equipment for more crushing and less grinding mineral processing.

The feed particle size of the multi-cylinder hydraulic cone crusher is ≤326mm, and the capacity is 72-1100 t/h. The multi-cylinder hydraulic cone crusher uses a hydraulic motor to adjust the fixed cone. Because the radius R of the spherical surface of the multi-cylinder cone crusher is relatively small, the swing radius is relatively small, and there are unstable phenomena such as overturning, poor contact between the main shaft and the bushing, and flying. These affect the normal operation of the machine. But its crushing capacity is relatively high. The multi-cylinder hydraulic cone crusher is suitable for crushing high-hardness materials, and the processing capacity is rather large.

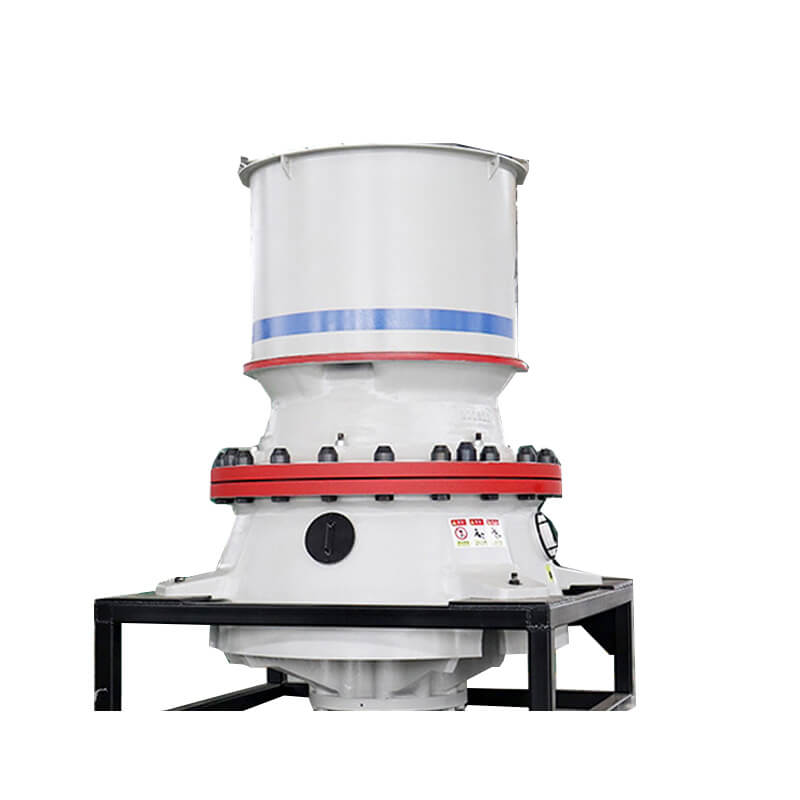

Single-cylinder Hydraulic Cone Crusher

The single-cylinder cone crusher is also called a single-cylinder hydraulic cone crusher. Its appearance is simple and compact. Through the unique design structure of the single cylinder at the bottom, three important functions of direct adjustment of the discharge port, prevention of iron overshoot, and cavity cleaning are completed. Therefore, there is no external discharge port adjustment mechanism and no external hydraulic cylinder or spring anti-iron device, and the overall shape and structure are simple and compact. Single-cylinder cone crushers are used for medium and fine crushing. It is widely used in metallurgy, construction, highway, chemical industry, and building materials industry. It is suitable for crushing high hardness and high abrasive ores and rocks, especially in crushing metal ore and construction sand and gravel.

The feed particle size of the single-cylinder hydraulic cone crusher is ≤560mm, and the capacity is 36-2181 t/h. The single-cylinder hydraulic cone crusher has a simple structure and a good discharge particle shape. Various cavity types combined with strokes can meet the needs of various particle sizes. The structure is simple and easy to maintain. However, the crushing force of this machine is slightly insufficient, especially unsuitable for crushing hard materials. Single-cylinder hydraulic cone crusher is mainly used in ultra-fine, fine, and medium crushing operations and industries with high requirements for the output particle shape.

We have rich experience in crushing equipment manufacturing. We supply all the above cone crushers. If you want to know more, please CLICK HERE to contact us.