As a key technology in the field of mineral processing, flotation technology is widely used in ore processing. Through crushing and grinding, different materials in the ore are separated into monomer particles. After reaching the appropriate particle size, flotation technology is used to extract valuable minerals. In this process, direct flotation and reverse flotation are two commonly used flotation methods, each with unique characteristics and applicable scenarios. Let’s follow the editor to learn about them.

Direct Flotation

Direct flotation is a flotation process in mineral processing. Its core is to add collectors to make the useful mineral surface hydrophobic and attached to bubbles to float to the surface of the pulp to form a foam layer according to the difference in the physical and chemical properties of the mineral surface while leaving the gangue minerals in the pulp as tailings. For example, in fluorite flotation, fluorite is preferentially floated as concentrate.

Basic principle

Based on the difference in hydrophobicity and hydrophilicity of the mineral surface, collectors (such as fatty acids and petroleum sulfonates) enhance the hydrophobicity of the target mineral to make it easy to attach bubbles; at the same time, inhibitors (such as sodium carbonate) inhibit the floatability of gangue minerals.

Process flow

Crushing and grinding → slurry mixing and adding (adjusting agent, collector) → flotation separation → dehydration and drying. For example, the direct flotation of siderite is divided into an acidic process (neutral/weakly acidic medium, adding fatty acid collector after desliming) and an alkaline process (weakly alkaline medium, no desliming, using oxidized paraffin soap, etc.).

Application

- High-siliceous phosphate ore (such as Wangji phosphate ore in Hubei, MgO content <1%).

- Fluorite, magnesium oxide ore, spodumene (acid-direct flotation).

- Fine-grained siderite (separation of iron minerals by surface hydrophobicity differences).

Advantages and limitations

- Advantages:simple process, high impurity separation efficiency (such as reducing Fe and Al content).

- Limitations: large amounts of reagents (such as a large amount of fatty acid collectors required for direct flotation of a high-silicon bauxite), and viscous foam make dehydration difficult.

Reverse Flotation

Reverse flotation refers to the process of selectively suppressing useful minerals and activating gangue minerals through reagents during the flotation process so that the latter are attached with bubbles and float to the surface of the pulp as tailings, while the useful minerals are retained in the tank as concentrates. In contrast to direct flotation, reverse flotation uses gangue minerals as the sorting target.

Basic principle

Based on the differences in the physical and chemical properties of the mineral surface. The floatability of useful minerals is reduced by inhibitors (such as starch and dextrin), while the hydrophobicity of gangue minerals is enhanced by activators (such as CaCl₂), and then the selective flotation of gangue minerals is achieved by collectors (such as amines and fatty acids).

Process flow

- Crushing and grinding: the ore needs to be crushed to a suitable particle size (e.g. iron ore reverse flotation often needs to be ground to less than 0.074mm) to ensure the dissociation of mineral monomers.

- Pulp adjustment and dosing: adjust the pH of the ore pulp (e.g. iron ore reverse flotation often uses pH=8~11), add inhibitors (e.g. starch inhibits hematite), activators (e.g. CaCl₂ activates quartz) and collectors (e.g. ether amine collects quartz).

- Floatation separation: aeration and stirring in the flotation machine, gangue minerals are scraped out with the foam, and useful minerals sink to the bottom of the tank.

- Concentration and dehydration: multiple sweeps to improve the concentrate grade, and the final concentrate is concentrated and filtered to obtain a high-purity product.

Application

- Calcium phosphate ore (separation of dolomite gangue).

- Desiliconization of bauxite (reverse flotation of silicate gangue).

- Desulfurization and dephosphorization of iron ore (such as reverse flotation of magnetite).

Advantages and limitations

- Advantages: energy saving (normal temperature operation), easy filtration of concentrate (such as less residual reagents in bauxite reverse flotation).

- Limitations: narrow applicability (poor effect on siliceous ores), poor selectivity of cationic collectors (such as low sorting efficiency of laterite nickel ore).

Difference Between Direct Flotation And Reverse Flotation

The flotation process is suitable for processing fine and micro-fine materials. If it is difficult to recover micro-fine mineral particles less than 10μm by other methods, the flotation method can be used. The flotation process is widely used to select non-ferrous metals such as copper, zinc, lead, nickel, gold, etc., and can also be used for roughing and concentrating ferrous metals and non-metals.

In practical applications, the flotation process uses a more direct flotation process, and only a small part of the ore will use the reverse flotation process. For example, it is better to use the reverse flotation process for phosphate ore, because the reverse flotation process can not only reduce production costs but also increase the concentrate rate. So what is the difference between these two flotation processes?

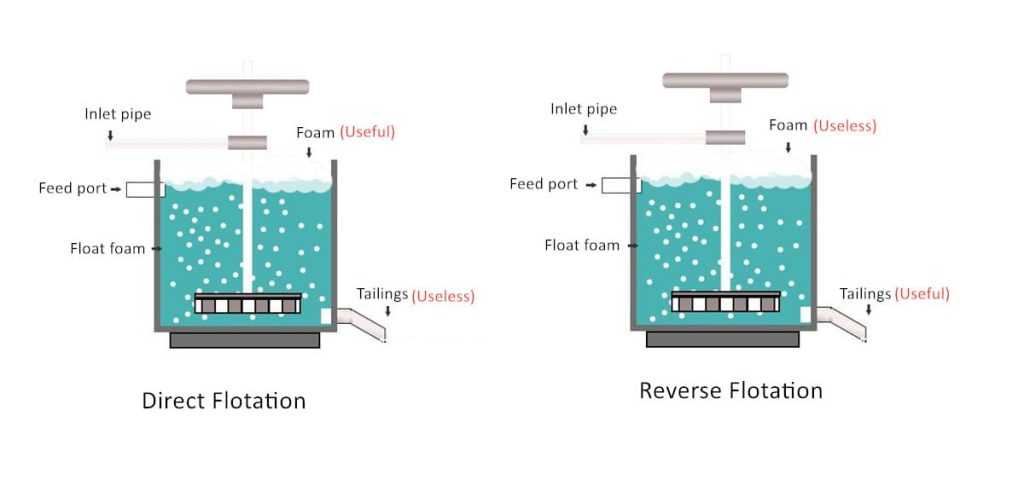

Different sorting value groups

The theory of direct flotation and reverse flotation in flotation technology is divided according to the different sorting value groups. direct flotation is a method of discharging useless minerals in the slurry as tailings, that is, the direct flotation process selects valuable minerals. Reverse flotation is to leave the required minerals in the flotation tank and scrape out the useless gangue minerals with the foam. Simply put, direct flotation selects useful ones, and reverse flotation selects useless ones.

Different selection of reagents

Direct flotation: Generally, the collector uses fatty acids or alkyl sulfates and petroleum sulfonates to flotate in weakly alkaline or weakly acidic pulp, and sodium carbonate is used to disperse the ore mud and precipitate multivalent harmful metal ions.

Reverse flotation: Taking the treatment of iron ore as an example, there are usually two methods, one collector uses the cationic reverse flotation method, and the other collector uses the anionic reverse flotation method. The cationic collector reverse flotation method is to adjust the pulp pH to 8-9 with sodium carbonate and use starch, dextrin, tannin, etc. to inhibit iron minerals. Amine collectors are used to float quartz gangue, among which ether amines are the best, followed by fatty amines; the specific method of the anionic collector reverse flotation method is to use sodium hydroxide or sodium hydroxide and sodium carbonate to adjust the pH value of the pulp to above 11, use starch, dextrin, etc. to inhibit hematite, use calcium chloride to activate quartz, and then use fatty acid collectors to collect the quartz activated by calcium ions. The product in the tank is hematite concentrate.

Comparative analysis of direct flotation and reverse flotation

Index | Direct Flotation | Reverse Flotation |

Target minerals | Useful minerals (such as phosphate minerals, fluorite) | Gangue minerals (such as dolomite, silicate) |

Agent types | Main collectors (fatty acids, amines) | Inhibitors (water glass, sodium hexametaphosphate) |

Applicable minerals | Mineral surfaces have poor natural hydrophobicity and require enhanced collection (such as oxide ores) | Ore that gangue minerals are easily inhibited (such as silicate and carbonate coexistence) |

Energy consumption | High (needs heating or fine slurry adjustment) | Relatively low (normal temperature operation) |

Environmental impact | Complex tailings treatment (large amount of foam) | Small tailings but fine particle size |

In summary, the main difference between direct flotation and reverse flotation in the flotation process is reflected in the valuable components separated, but their common goal is to extract valuable minerals from the material. These two methods have different application fields and advantages and disadvantages, so in actual production, we can choose the most suitable method according to the specific situation.