Diamond refers to polished diamond. Diamond is a natural mineral and the raw stone of diamond. A diamond is a simple crystal composed of carbon formed under high pressure and high-temperature conditions deep in the earth. As a mineral resource, the market price of diamond is indeed high, but the content of diamond in the ore is indeed very low. To extract diamond from the ore, it must go through a process of beneficiation and purification.

Can a jig separator separate the diamond?

The specific gravity of diamonds is 3.5-3.52, larger than that of ordinary gangue. Whether it is a placer or primary ore, diamonds can be extracted from the ore through gravity separation, requiring a jig. Because the jig is an automated mechanical mineral processing equipment that can achieve large-scale and high-efficiency production, it is of great significance for the mineral processing of extremely low-content placer ores and primary diamond ores. The main function of the jig separator in diamond beneficiation is rough selection to discard a large amount of waste rock and sand, and then enter the beneficiation process. This can ensure the recovery rate of diamond beneficiation and greatly improve the beneficiation efficiency.

After crushing, screening, and other processes, the raw diamond ore enters the jig for gravity separation. In the sorting tank of the jig, diamonds with a larger specific gravity are separated from waste rocks with a smaller specific gravity, and the final concentrate is obtained Entering the selection process again, you can use selection equipment such as ointment concentrators and X-ray sorters to select diamonds. Diamond placer beneficiation must be washed and screened before entering the jigging beneficiation process. The final concentrate then enters the beneficiation process to obtain the final diamond.

Jig separator separate alluvial/placer diamond

The dissociation degree of diamonds and sandstone in placer mines is very high, and no conjoined body exists. Therefore, there is no need to use crushing to break the conjoined bodies. The mineral processing process is much simpler than kimberlite diamond mines. Only through washing, screening, and gravity selection can the diamond ore be enriched to the greatest extent, and then through manual hand selection or ointment dressing, the rough diamonds can be selected. The gravity selection link is particularly important because it is the stage where most of the sand and gravel in the diamond placer mine is discarded and where the diamond ore is enriched to the greatest extent. The equipment used in this stage is the jig.

The jig can sort gravity based on the difference in specific gravity between diamonds and sand and gravel, thereby separating diamonds with a larger specific gravity from sand and gravel with a smaller specific gravity. Although the sorting accuracy is not yet 100%, it can at least maximize the For rich diamond mines, using a jig can free up dozens of manual washing labor forces, and it can operate continuously, with stable production indicators and without excessive management. This is the advantage of mechanized washing of diamond mines. With the jig, selecting diamonds from placer mines is very simple. Jigs have been used in diamond placer beneficiation in Angola, Liberia, Congo, and other countries and have achieved ideal results.

Jig Separators Classification

There are many types of jig separators. According to the different ways of causing the water flow in the jig to produce vertical alternating movements of rising and falling, jig separators can be divided into the following types: eccentric link-type jigs (including piston jigs and diaphragm jigs), pistonless jigs, hydraulic agitation jig, moving screen jig, etc.

At present, the mineral processing plant mainly uses diaphragm jig separators. The different positions of the diaphragm can divide jig separators into

①Upward-moving diaphragm jig (also called typical Val type), its diaphragm chamber is located in the upper part of the body;

② Down-moving conical diaphragm jig, its diaphragm is located under the jig chamber;

③ Side-moving diaphragm jig, its diaphragm is located on one side of the jig chamber, including trapezoidal jig, rectangular jig, etc.

The water movement in the pistonless jig is not driven directly by the piston or diaphragm but by the compressed air sent by the blower to make the water move up and down alternately. This kind of jig is generally used in the coal preparation industry.

The moving screen jig uses a screen to move up and down in the water, causing rising and falling water flows. The simple hand-operated jigs used in some small processing plants in my country belong to this type.

Jig Separator for Diamond Process

Since the content of diamonds in the ore is very low, extracting diamonds usually requires combining various beneficiation methods through two stages of roughing and concentrating. Let’s take a look at the process flow of diamond placer beneficiation:

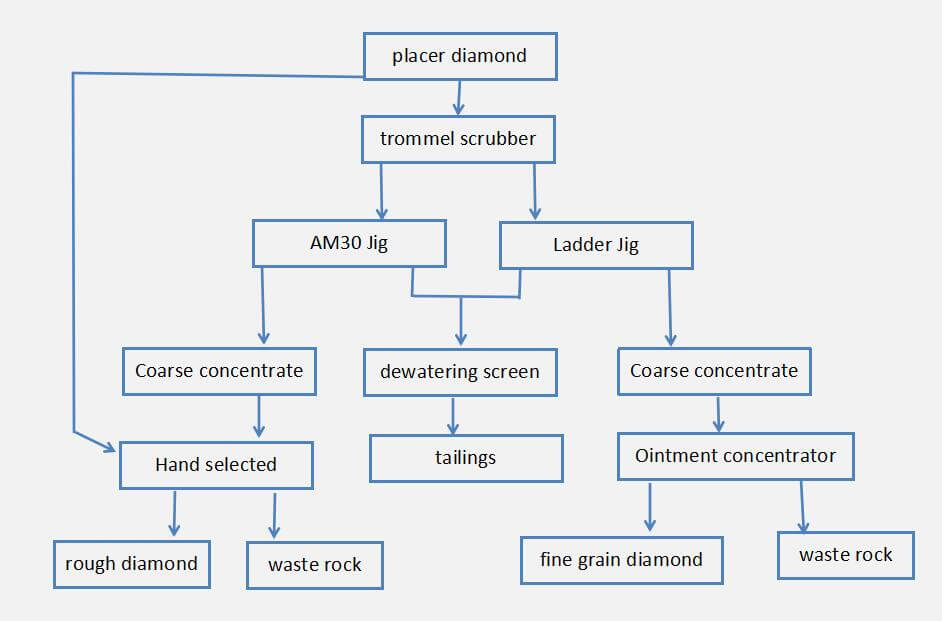

Alluvial diamond is washed by a cylinder washing machine to wash away the soil adhering to the surface of the ore while reducing the sticky soil in the ore sand and improving the selectivity of the ore. The cylinder washing machine washes and screens the raw ore into three particle sizes: 0-8mm, 8-30mm, and +30mm. The diamond sand ore of 0-30mm particle size enters the large particle jig for washing, 0-30mm. The 8mm grade diamond sand ore enters the ladder jig for washing. The final tailings are dewatered using a dewatering screen and then discharged. The coarse concentrate from the large grain jig is mixed with +30mm grade sand ore and enters the manual selection process. , using a manual hand selection method to recover coarse-grained diamonds. Medium and fine-grained diamond placers with a 0-8mm particle size enter the trapezoidal jig machine. The coarse concentrate obtained after washing enters the ointment concentrator to extract fine-grained diamonds.

Diamonds are divided into primary ores and placer deposits based on their origin. The washing and purification of placer ore is relatively simple, but because it often contains gold, ilmenite, quartz sand, rutile, garnet, and other minerals, gravity separation, ointment separation, and X-ray analysis are usually required during the washing process. Various methods, such as selection, are used in combination to achieve the purpose of separately recovering different types of ores.

The washing of diamond placer generally uses jig roughing and an ointment concentrator for fine selection. The specific gravity of diamond is 3.52, which has a certain specific gravity difference with gangue. However, because there are often other heavy minerals in the ore, the diamond concentrate output rate of the gravity separation process is high. The jig concentrate needs to be selected. The commonly used method is ointment beneficiation. Oil beneficiation has a low concentrate output rate and high beneficiation accuracy but poor lipophilicity. The diamond recycling effect is not ideal. Coarse-grained diamond ore is often extracted by hand selection after washing and jigging, and coarse-grained diamonds are recovered by manual hand picking.

To extract diamonds from ore, a jig and an ointment concentrator alone are far from enough. Usually, more ideal and suitable washing equipment and methods need to be selected based on the specific properties and characteristics of the ore. Only in this way can the purpose of extracting diamonds be achieved. Diamond beneficiation is the close cooperation of equipment and a strict examination of beneficiation technology and experience. Any unsatisfactory aspect will cause diamond washing failure.