Copper is an important metal widely used in various industries due to its excellent electrical conductivity, thermal conductivity, and corrosion resistance. Here is a detailed introduction to the importance of copper and its development trends.

Copper Applications/Importance

Electrical and Electronic Fields

- Conductive Materials: Copper has excellent electrical conductivity and is widely used in wires, cables, busbars, and motor windings.

- Electronic Components: Copper makes printed circuit boards, connectors, and semiconductors.

Building and Infrastructure

- Pipes and Pipe Fittings: Copper is widely used in water supply pipes, HVAC systems, and gas pipes due to its antibacterial and corrosion resistance.

- Building Materials: Copper is used in roofing, exterior walls, and decorative materials for its beauty and durability.

Transportation

- Automotive Industry: Copper plays a key role in automotive electrical systems, radiators, and braking systems.

- Railways and Aviation: Copper is used in railway electrification systems and avionics.

Industrial Equipment

- Heat Exchangers: Copper’s excellent thermal conductivity makes it an ideal material for heat exchangers and condensers.

- Industrial Machinery: Copper alloys are used to make high-strength, wear-resistant mechanical parts.

Renewable Energy

- Wind and Solar: Copper is used in wind turbines and solar panels and is a key material in the renewable energy sector.

- Electric Vehicles: With the development of electric vehicles, the demand for copper continues to grow, mainly for batteries, electric motors, and charging infrastructure.

Copper Development Trends

Demand Growth

- Global Electrification: With the global transition to electrification and renewable energy, the demand for copper continues to grow. Especially in developing countries, the expansion of electrical infrastructure will significantly increase the demand for copper.

- Electric Vehicles: The rapid growth of the electric vehicle market will significantly increase copper consumption, as electric vehicles require more copper than traditional internal combustion engine vehicles.

Sustainability and Recycling

- Copper Recycling: Copper is one of the most easily recycled metals. Recycling copper saves resources and reduces energy consumption and environmental impact. In the future, copper recycling will become an important source of copper supply.

- Green Technology: In response to environmental issues in the copper production process, more technologies and processes will be developed and applied in the future to reduce environmental pollution and carbon emissions.

Technological Innovation

- New Material Development: With the advancement of technology, new copper alloys and composite materials are constantly being developed to meet the needs of different application areas.

- Smart Manufacturing: The application of Industry 4.0 and smart manufacturing technologies will improve the efficiency and quality of copper product production.

Market Volatility and Supply Chain Management

- Price volatility: The copper market price fluctuates greatly due to supply and demand, geopolitics, and economic conditions. Enterprises need to cope with market uncertainties through effective supply chain management and risk management strategies.

- Global supply chain: Ensuring a stable supply of copper requires global supply chain management, especially in the face of policy changes in resource countries and transportation logistics challenges.

As a key industrial metal, copper has irreplaceable importance in the development of modern economy and technology. As the world transitions to green energy and electrification, the demand for copper will continue to increase. At the same time, through technological innovation and sustainable development strategies, the copper industry will continue to adapt to new challenges and opportunities and achieve more efficient and environmentally friendly development.

Copper Ore Processing Technology

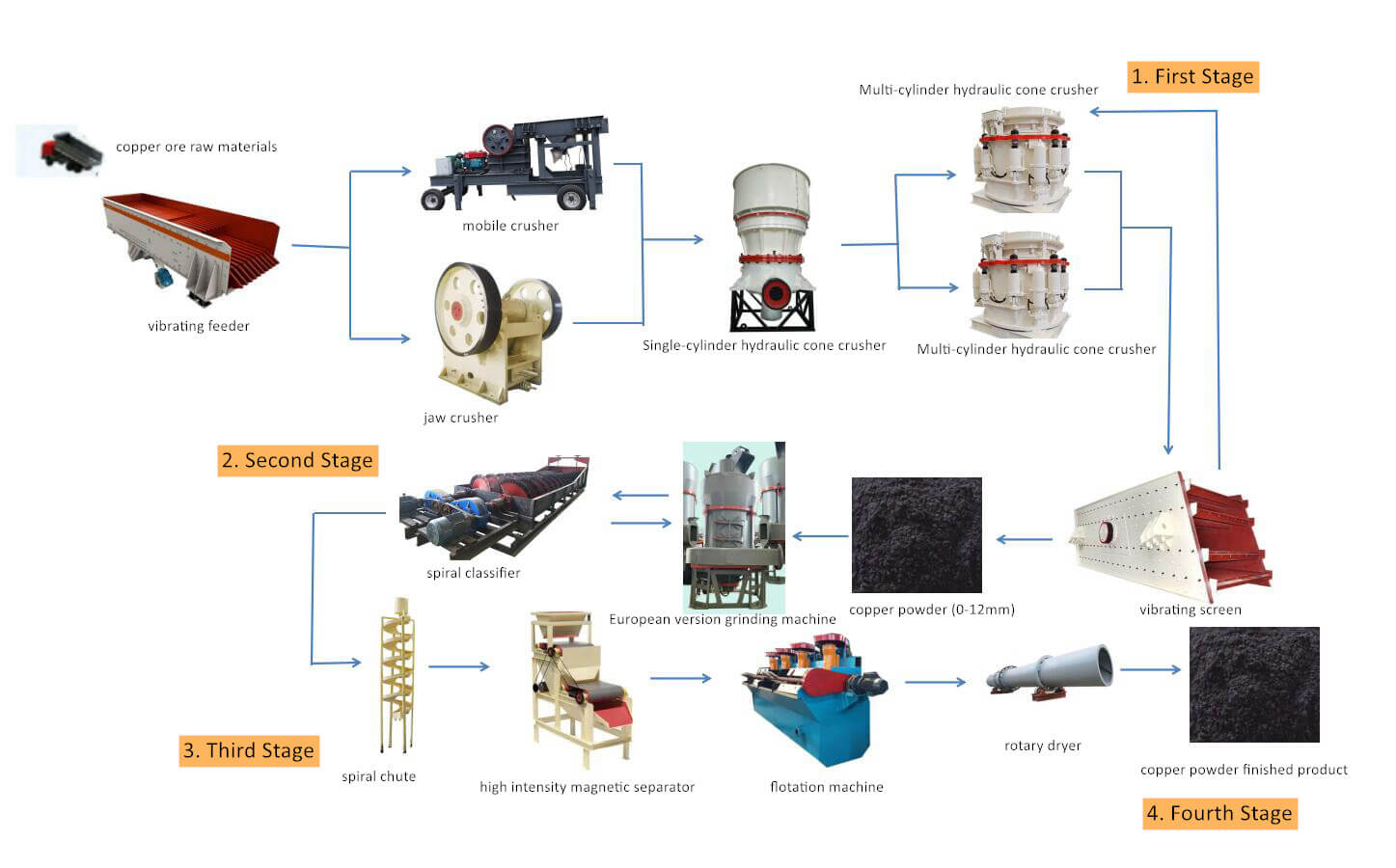

The processing and production technology of copper ore mainly includes three processes: crushing, grinding, and beneficiation. The modern copper ore crushing method adopts three-stage closed-circuit crushing, which can not only complete the crushing and partial dissociation of the ore, but also improve the efficiency of subsequent grinding. During the grinding process, the two-stage one-closed grinding process can make the copper ore more fully ground. In the beneficiation process, the mixed flotation process is one of the more successful new processes in recent years.

Copper Ore Crushing

The first stage: Crushing and screening – three-stage closed-circuit crushing

The large pieces of copper ore are evenly fed into the jaw crusher or the mobile crushing station for coarse crushing by the vibrating feeder.

The coarsely crushed copper ore is screened by the vibrating screen and sent to the single-cylinder hydraulic cone crusher for medium crushing through the belt conveyor.

The copper ore material after medium crushing is then sent to the multi-cylinder hydraulic cone crusher for fine crushing.

The second stage: grinding – two-stage one-closed grinding

The 0-12mm copper ore powder after the vibrating screen is evenly fed into the grinding machine for grinding.

The ground material is screened by a spiral classifier, and the material that does not meet the requirements is returned to the grinding machine for further grinding.

The third stage: ore dressing – mixed flotation process

The copper ore powder that meets the requirements is fed into the flotation machine for mixed flotation.

The copper ore powder after flotation is fed into the dryer for drying, and finally, copper concentrate is obtained.

Copper Ore Crushing Equipment

Jaw crusher: Used for primary crushing and processing large pieces of ore.

Single-cylinder hydraulic cone crusher: Suitable for medium crushing, processing harder ores, with a large crushing ratio.

Multi-cylinder hydraulic cone crusher: Used for fine crushing, with the characteristics of high efficiency and energy saving.

Through this scientific processing technology and advanced equipment configuration, the crushing, grinding, and beneficiation of copper ore can be completed efficiently and stably to meet the subsequent smelting needs and improve resource utilization.

Copper ore crusher equipment is a special crushing equipment for crushing copper ore. The quality of the crusher is closely related to the development of the mine. Therefore, when facing many brands of crusher equipment on the market, choosing a set of excellent, reliable, high-quality, technologically advanced, and economical copper ore crusher is the key to safe production. The copper ore crushing equipment produced by JXSC mineral is a special equipment designed for copper ore crushing.

JXSC mineral copper ore crusher, as the name suggests, is a crusher equipment used for crushing and sand and gravel production. Applicable materials include river pebbles, granite, basalt, iron ore, limestone, quartzite, diabase, etc. Application areas include gravel fields, mining fields, coal mines, concrete mixing stations, dry mortar, power plant desulfurization, quartz sand, etc. Copper ore crusher is affordable, advanced technology, stable operation, and high efficient. Not only is the equipment of excellent quality, but the price is also in line with the market situation. JXSC sells directly from the factory, and there is no need to exploit the interests of suppliers in the middle. The price is a greater competitive advantage compared to the market price. Moreover, JXSC is considerate and thoughtful in after-sales service. You can buy equipment at a price far lower than the market price and enjoy excellent and thoughtful service, so you can buy with confidence.