Copper is an important non-ferrous metal related to the national economy and people’s livelihood. It has properties such as electrical conductivity, thermal conductivity, tensile strength, and wear resistance. It is widely used in electric power, electronics, daily necessities, machinery, transportation, and other fields.

In the past ten years, beneficiation workers have researched various types of copper ores, copper-containing polymetallic ores, and copper smelting slag, especially low-grade, complex and refractory copper resources. It made new progress in chemical processing, comprehensive recovery of associated valuable components, improvement of the technical level of comprehensive utilization of secondary copper resources, research and development and application of high-efficiency and low-toxicity new mineral processing agents, and reduction of mineral processing costs.

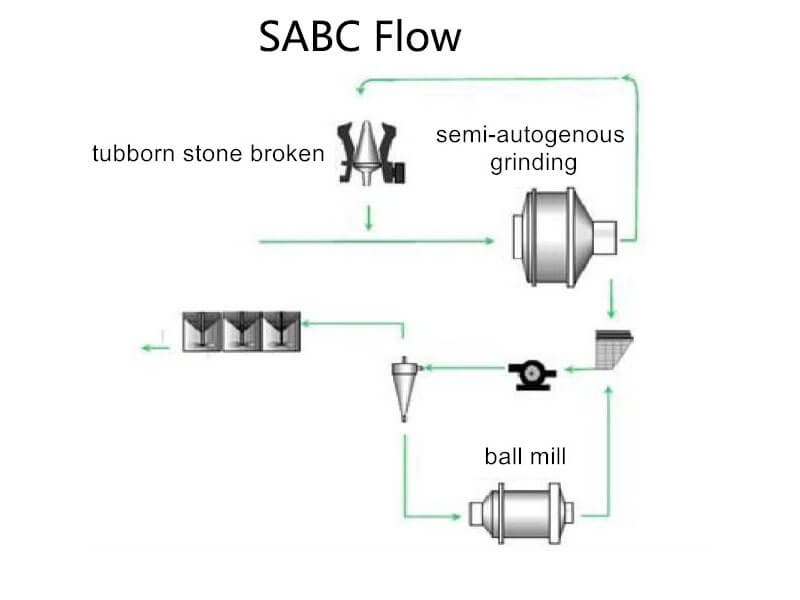

In the crushing and grinding stage, the concentrator always adheres to the principle of “more crushing and less grinding, and crushing instead of grinding”, and develops and optimizes new equipment and processes that save energy and reduce consumption. With the continuous reduction of copper ore grade, the old concentrator has improved the crushing and screening efficiency, increased the pre-screening equipment before grinding, increased the filling rate of the ball mill, improved the classification efficiency of the cyclone, and adopted automation based on the traditional crushing and grinding process. The control system and other means have improved the grinding efficiency and achieved the purpose of saving energy, reducing consumption, and reducing the cost of beneficiation. The application of the SABC process (semi-autogenous grinding + ball milling + stubborn stone crushing) in large-scale concentrators in China and the research and application of the HPGR grinding process (high-pressure roller grinding) in copper ore grinding process are gradually expanding.

Mineralogical Research of Ore Process

Mineralogical research on the ore process is essential in formulating the mineral processing process and analyzing production problems. In recent years, there has been much research on copper ores, including the low-grade, complex & difficult to handle, closely embedded copper and copper polymetallic ores, copper smelting slag, etc. It promoted the study and application of metallurgical union, a combined process of various beneficiation methods.

The ore grade for beneficiation has gradually decreased with the continuous exploitation of copper ore resources. The production indicators and economic benefits have been improved by optimizing the grinding and flotation process, expanding the production scale, and reducing the production cost of the beneficiation plant. The low-basicity copper-sulfur separation process is further applied to industrial production to recover valuable components such as associated gold, silver, and sulfur in copper ore. Significant progress has also been made in the research and application of the combined gravity separation and flotation process. For the recovery of muddy and carbonaceous copper ore, in addition to the traditional “pre-desliming (decarbonization)-flotation” process, flotation-gravity separation, the research on the combined process and new inhibitors have also achieved specific results.

Copper Oxide Beneficiation

There are many kinds of copper oxide minerals, some of which have high binding oxidation rates, strong hydrophilicity, high mud content, and many associated valuable components, so the difficulty of flotation increases. Different types of copper oxide ores have significant differences in flotation, and flotation is often used to treat copper oxide ores in production.

Currently, the treatment methods of copper oxide ore mainly include the sulfide flotation method, direct flotation method, pretreatment-flotation method, and flotation-leaching method.

- Sulfidation flotation: Generally, sulfidation flotation is suitable for carbonate-containing copper oxide ores, such as malachite, azurite, cuprite, etc.

- Direct flotation method: The direct flotation method includes organic acid flotation and amine collector flotation, and is suitable for the flotation of copper oxide minerals whose gangue is silicate or contains lead and zinc oxide.

- Pretreatment – flotation and flotation – leaching method: The method is primarily suitable for copper oxide ores that cannot be effectively recovered by a single flotation method, such as refractory copper oxide ores with high content of silicic malachite and a close symbiotic relationship. Due to the complex process and high beneficiation cost, it restricts its wide-scale industrial application. Currently, this process only has application cases in refractory high-grade copper oxide ores recovery.

Copper-bearing Polymetallic Ore

Copper-bearing polymetallic ores mainly include

- Copper-lead-zinc polymetallic ores.

- Copper-molybdenum ores.

- Copper-zinc ores.

- Copper-bismuth ores.

- Copper-nickel ores.

Such ores are often difficult to separate by flotation due to the complex mineral composition, the close symbiotic relationship between minerals, and the slight difference in flotability among metal minerals. Most of the research on the flotation of this type of ores has focused on the new technology and application of new chemicals for separating copper from lead-zinc, molybdenum-bismuth, and nickel-sulfur minerals, and many recent scientific and technological achievements have been obtained.

Copper Smelting Slag Treatment

The treatment methods of copper smelting slag mainly include pyrolytic dilution, wet leaching, and beneficiation enrichment.

Due to the high cost, complex process, and serious environmental pollution, it is less use pyrolytic dilution and wet leaching in industrial applications.

Although the beneficiation enrichment method requires a large area of slag slow cooling field and high infrastructure investment, it has a high recovery rate of copper and associated gold and silver, low energy consumption, and low cost. It has been applied in large-scale industrial applications and achieved significant benefits.

Copper Beneficiation Wastewater Treatment

China

Commonly used methods such as natural degradation, coagulation sedimentation, neutralization, adsorption, oxidative decomposition, etc., The wastewater recycling rate is relatively low, and there is still much room for research in this technical field.

Abroad

Commonly used methods such as precipitation, oxidation, electrodialysis, ion exchange, activated carbon adsorption, flotation, etc., The recycling rate of mineral processing wastewater can be above 95%.

It must consider mineral beneficiation automation in modern mineral processing plants. In recent years, with the development of applied physics and computer technology, such as acoustics and optics, the research and application of mineral processing automation technology have made significant progress, which has fundamentally changed the production of mineral processing plants. Problems include significant operating errors, inefficient management, and unstable production indicators.