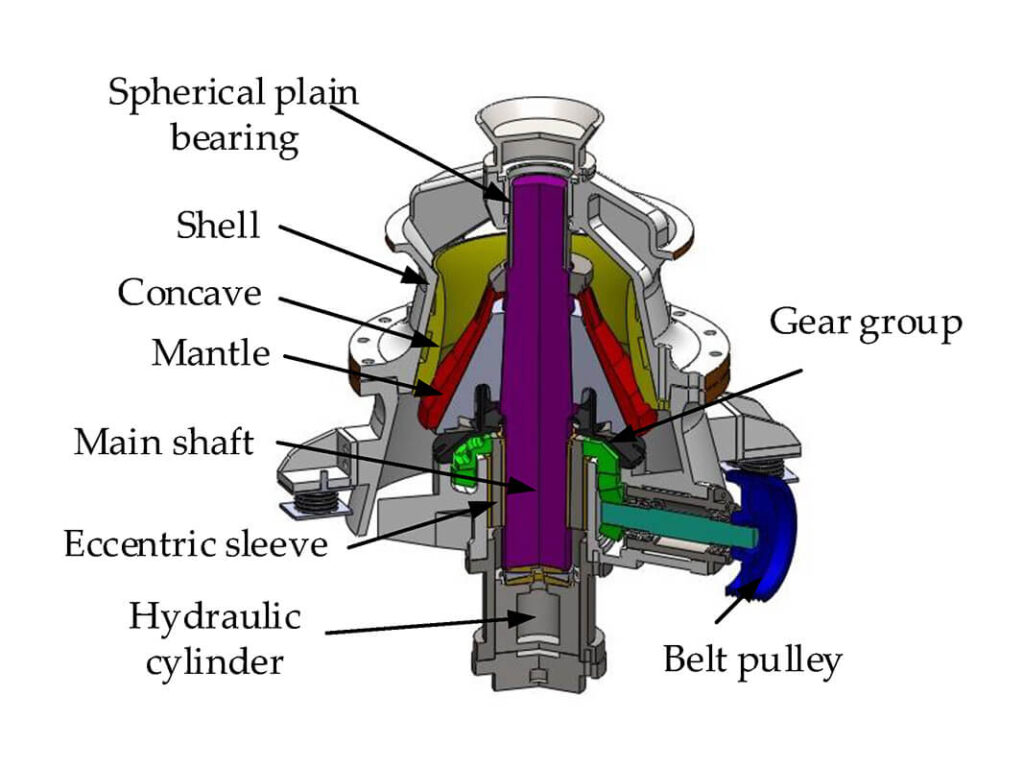

A cone crusher is a crushing equipment commonly used in the mining and aggregate industries. It’s known for its efficiency in crushing hard and abrasive materials. The cone crushers are widely used in quarrying, mining, and construction. It is used to crush materials by squeezing them between a mantle and a concave, which are located inside a crushing chamber. Closing the gap between the mantle and the concave causes the crushing action.

The cone crusher has a large crushing ratio, high efficiency, low energy consumption, and uniform particle size. It is suitable for medium and fine crushing of various ores and rocks. It is a commonly used crushing equipment in mineral processing and sand-making production lines! Because most crushed materials are high-hardness ores, spare parts’ wear, and tear is inevitable in the daily work of cone crushers.

Cone Crusher Wear Parts

Cone crusher wear parts are components that experience wear and tear during the crushing process and need to be replaced periodically to ensure the efficient operation of the cone crusher. These wear parts are designed to withstand high-stress crushing conditions and are typically made of durable materials. The cone crusher wearing parts include mantle, concave/bowl liner, bowl adapter ring, main frame liner, feed cone/hopper liner, torch rings and burning rings, eccentric bushings, adjustment rings, etc.,

- Mantle: The mantle is a wear-resistant liner that covers the cone crusher’s main shaft and forms the crushing surface against the concave. It protects the main shaft from wear and provides a crushing chamber for the material.

- Concave/Bowl Liner: The concave, also known as the bowl liner, is a wear-resistant liner fixed to the bottom of the cone crusher’s crushing chamber. It supports the mantle and forms the crushing surface against which the incoming material is crushed.

- Bowl Adapter Ring: The bowl adapter ring is a component that connects the concave to the main frame of the cone crusher. It helps to secure and position the concave in place.

- Main Frame Liner: The main frame liner is a protective liner covering the cone crusher’s main frame. It helps to reduce wear on the mainframe and provides additional support to the other wear parts.

- Feed Cone/Hopper Liner: The feed cone or hopper liner is a wear-resistant liner that covers the top of the cone crusher’s feed hopper. It protects the hopper from wear caused by the impact of the incoming material.

- Torch Rings and Burning Rings: Torch rings and burning rings are components installed between the mantle and the main shaft of the cone crusher. They help to distribute the heat generated during the crushing process and prevent the mantle from overheating.

- Eccentric Bushings: Eccentric bushings are located on the main shaft of the cone crusher and provide support and rotational movement to the main shaft. They can experience wear and need to be replaced to maintain the proper functioning of the cone crusher.

- Adjustment Rings: Adjustment rings adjust the cone crusher’s closed side setting (CSS). They are typically threaded and can be rotated to change the gap between the mantle and concave, controlling the size of the crushed product.

How to Replace The Cone Crusher Wear Parts?

Mantle & Bowl Liners

Replacement time

The mantle and bowl liners are essential components of the cone crusher. The material is crushed directly in the crushing chamber composed of the two. Therefore, the mantle and bowl liners’ wear is relatively serious. In general, their service life is usually 5-6 months.

Of course, due to different processing materials, working hours, and intensity, other users also have differences in daily maintenance and maintenance, and the specific replacement cycle cannot be generalized. During the maintenance process, it is found that the wear is serious, and it must replace the parts immediately.

Spindle and Taper Bushing

Under the normal working condition of the crusher, both the main shaft and the cone bushing have obvious wear marks at the height of about 400mm from the top of the cone bushing. If the main shaft and the cone bush wear heavily at the lower part and light at the upper part, the movable cone will be slightly unstable at this time, and the crusher cannot operate normally. If there is local contact between the main shaft and the taper bushing at the lower end, the taper bushing will be cracked and damaged.

Thrust Plate and Gear

The thrust plate wears more seriously along the outer circle. Due to the high linear speed of the outer ring, the wear is faster than that of the inner ring. And because of the skew of the eccentric shaft sleeve, its outer ring wear is aggravated. When the crusher is running, the large bevel gear moves around the crusher in a circle with the radius of the gap between the straight bushes, which will cause additional impact vibration and wear during the gear operation, shortening the gear’s life.

Frame With Spherical Bearings

The wear of the spherical tile is a process that gradually develops from the outer ring to the inner ring. In the later stage of use, the moving cone may be unstable, and the main shaft may be stuck at the lower opening of the cone bushing, resulting in cracks and damage to the lower opening of the cone bushing and even the phenomenon of “speeding” and damage to the spherical tile crack.

Eccentric Bushings and Straight Bushing

The wear of the eccentric bushing shows along the height direction of the eccentric bushing, the upper part is heavily worn, and the lower end is slightly worn. The wear on the upper part is also gradually reduced from top to bottom. During the operation of the cone crusher, the straight bushing often moves upward, and the straight bushing cracks. Cracks are more likely to be caused by the straight bushing running up, but when the straight bushing is cracked, the debris generated will cut the surface of the center hole of the frame and make it round. The cracked debris will especially damage the eccentric bushing, making the whole machine. The working conditions deteriorated, and even serious accidents were caused.

Bushing

Replacement time

The wear of the cone crusher shaft sleeve will seriously affect production, and it must replace the shaft sleeve when the shaft sleeve is worn to a certain extent.

Replacement method

Replacing the bushing also requires specific skills. When removing the bushing, the first choice is to separate the cutting ring of the bushing to prevent damage to the main shaft, and then the bushing can be easily removed by turning the iron rod counterclockwise.

Taper Sleeve

Replacement time

Check the taper sleeve regularly, replace it in time, and determine the replacement cycle according to the hardness of the material processed and daily working hours.

Replacement method

When replacing, add zinc alloy inside to prevent the bush from rotating, and don’t leave a gap between the cone bushing and the eccentric shaft.

JXSC can provide different types of cone crushers such as Simmons cone crushers, hydraulic cone crushers, and cone crushers with advanced functions to meet specific crushing requirements.