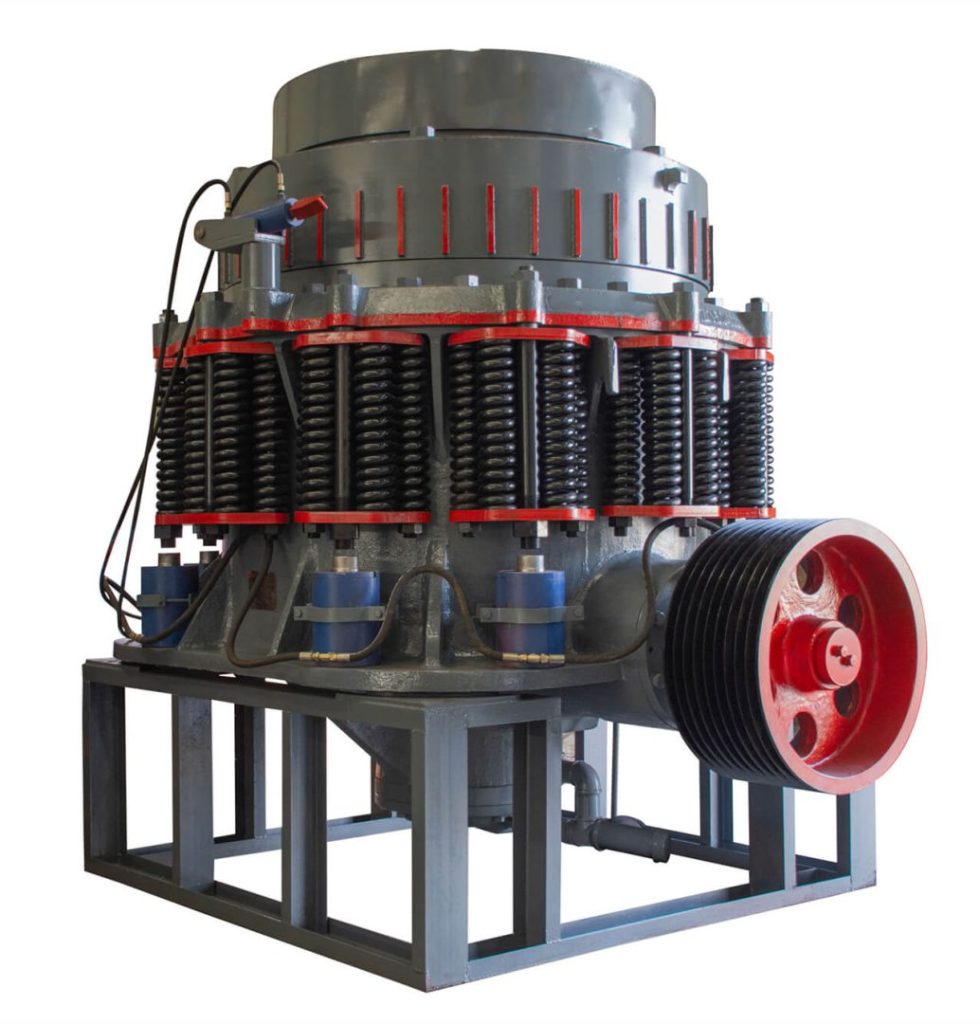

Cone crusher is an important secondary crushing equipment and plays an important role in the production line. In the production process, due to improper operation or equipment abnormality, cone crusher will cause blockage during the production process, forcing the equipment to stop, wasting a lot of time cleaning up the accumulated materials, and affecting the efficiency of the entire production line. So, what is the specific cause of the blockage, and how to deal with it?

Causes of Cone Crusher Blockage

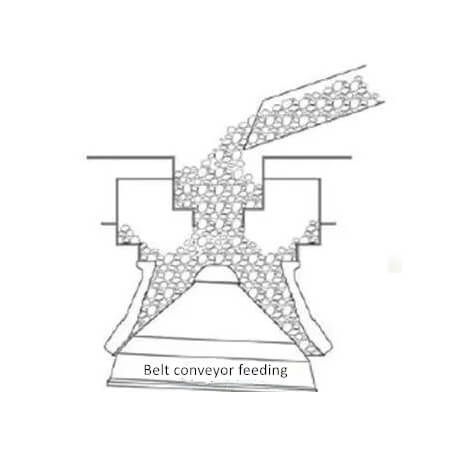

Improper feeding

Due to different types of materials, the selected cone crusher will have certain differences. If the crushed material is not suitable for the cone crusher, it is very easy to cause damage to the cone crusher parts; in addition, it may be the wrong feeding method. If too much material is fed at one time, the cone crusher will be overloaded, which will also cause the cone crusher to block. If the feeding speed is too fast or the feeding amount is too large, it will exceed the processing capacity of the cone crusher, and the material will not be processed in time and will cause blockage.

Improper discharge at the discharge port

The size of the discharge port of the cone crusher can be adjusted. In production, if it is not adjusted according to actual requirements, the crushed material cannot be discharged in time and stays in the crushing chamber of the cone crusher; in addition, the volume of the material to be crushed is too large, which exceeds the parameter range of the discharge port and cannot be discharged. Both phenomena are likely to cause the cone crusher to block.

Cone crusher equipment failure

During the operation of the cone crusher, if the equipment motor fails, it will cause damage to the pulley and bearing, slippage of the transmission belt, and even combustion. The motor of the cone crusher cannot normally provide kinetic energy for the equipment, which will also cause the cone crusher to block. Internal damage to the cone crusher, such as structural damage, components falling off, etc., can also cause blockage.

There is debris in the crushing chamber

If there is debris in the crushing chamber of the cone crusher and it is not handled in time, the material put into the crushing chamber of the cone crusher cannot be effectively crushed due to insufficient crushing space. The presence of debris affects the output of the material and causes the cone crusher to block.

How to Prevent Cone Crusher Blockage?

1. Inspection before production

Before starting the production of cone crusher, check all parts of cone crusher, check whether all fasteners are firm, check whether the motor wiring is correct, check whether the pulley tightness is appropriate, check whether the voltage of cone crusher working site is normal, check whether there is debris in the crushing chamber, etc., and clean up the debris in the crushing chamber in time to ensure the working conditions of cone crusher normal production.

2. Requirements when feeding

When feeding materials into the cone crusher, attention should be paid to the following two aspects: first, the feeding should be kept uniform and the feeding amount should not be too much; second, the feeding properties should meet the requirements, that is, the particle size, hardness and moisture content of the material should not be too large, too hard or too much, to avoid the material sticking to the inner wall of the crushing chamber, thereby causing a blockage in the equipment.

3. Processing before feeding

If there are materials that do not meet the feed properties of the cone crusher, they must be processed in advance. For example, blasting large pieces of material, pre-screening materials with more fine sand, sun drying and drying materials with more water, etc., to ensure the dryness and purity of the material, and the material cannot contain too many other impurities.

4. Timely adjust the discharge port parameters

The poor discharge of the cone crusher is one of the direct factors leading to equipment blockage. Therefore, in the production process of the cone crusher, attention should be paid to changing the discharge port parameters according to the changes in the feed properties, so that the crushed materials can be discharged smoothly. When large pieces of debris such as iron blocks enter the cone crusher, the width of the discharge port can be appropriately increased so that the debris can be discharged smoothly to reduce equipment blockage.

5. Reduce component wear

If the main crushing components of the cone crusher are seriously damaged, the crushing effect of the material will be reduced, which will indirectly lead to equipment blockage. Therefore, in production, attention should be paid to reducing the wear of the cone crusher, doing a good job of maintenance of the cone crusher, reducing blockage, and improving the productivity of the cone crusher.

Cone crusher material blockage will not only cause equipment downtime but also take a lot of time to clean up the blocked materials, which will have a serious impact on production efficiency. In order to ensure the continuous and efficient operation of the cone crusher, it is necessary to actively explore solutions to prevent material blockage. By optimizing the raw material supply system, adjusting crusher parameters, and enhancing equipment maintenance, the occurrence of raw material blockage can be effectively reduced or avoided.