Coal gangue is a fixed coal mining, washing, and processing product. It is a black-gray rock with lower carbon content and harder than coal associated with coal seams during the coal formation process. And its chemical composition is SiO2, Al2O3, Fe2O3, MgO, CaO, TiO2, etc.

What Minerals Do Coal Gangue Mainly Contain?

Coal gangue refers to the waste or by-product produced when coal is extracted from coal mines. These wastes usually include coal gangue (without valuable crushed coal and gangue), rocks, soil, and other minerals. The composition and mineral content of coal gangue can vary depending on the type of coal mine and geographic location. Generally speaking, coal gangue may contain some of the following main minerals and components:

- Coal: One of the main components of coal gangue is coal itself, including different types of coal, such as stone coal, lignite, anthracite, etc.

- Rock: Coal gangue usually contains a large amount of rock. These rocks may be rock layers above and below the coal seam or other stones in the deposit.

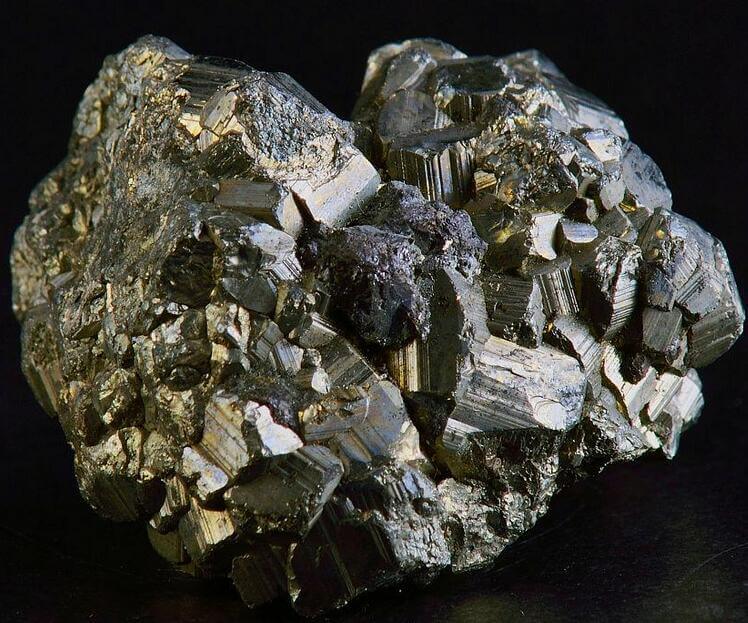

- Pyrite: As you mentioned, coal gangue may contain pyrite, a mineral containing iron and sulfur.

- Goethite: Sometimes, coal gangue may also contain pyrite, which is an iron-containing mineral.

- Quartz: Coal gangue often contains quartz, which is a silicate mineral.

- Calcite: Calcite is a mineral containing calcium and carbon that may also be found in coal gangue.

- Sulfides: Besides pyrite, other sulfides may also exist, such as chalcopyrite, zincite, etc.

How to Deal With Coal Gangue?

Processing coal gangue is usually essential in coal mining because it involves environmental protection and resource utilization issues. The following are some standard coal gangue treatment methods:

- Coal gangue stacking: Stack coal gangue in designated areas and adopt appropriate stacking methods to reduce the impact on the surrounding environment.

- Reuse: Sometimes, specific components in coal gangue can be processed through technical means to be used for other purposes, such as road construction, filling materials, etc.

- Dust reduction measures: Take measures to reduce the weathering and flying of coal gangue to reduce particulate matter pollution.

- Environmentally friendly treatment: Use environmentally friendly treatment methods, such as flotation, oxidation, pickling, etc., to reduce the content of harmful components in coal gangue.

- Ecological restoration: Carry out ecological restoration of coal gangue areas to restore their natural environment and reduce adverse effects on the ecosystem.

Specific treatment methods are adjusted according to the composition and properties of coal gangue. In any processing process, we should consider environmental and safety factors to ensure that coal gangue treatment is sustainable and causes minimal impact on the surrounding environment.

What Are The Uses of Coal Gangue Powder?

- Coal gangue power generation

Coal gangue grinding adopts fluidized bed technology. When the carbon content is greater than 20%, it can be used as energy and can be used to generate electricity. - Recycling of coal and pyrite

Coal gangue adopts composite dry coal preparation, cyclone, and heavy medium separation. When the coal content exceeds 20%, coal can be recovered through coal preparation. This way, the GKLM vertical mill must be used to grind the coal gangue into coal gangue powder. - Coal gangue grinding powder is used for building materials

After the coal gangue is ground, it can be used in gangue brick making, cement manufacturing, lightweight aggregate production, coal gangue block building, etc. - Coal gangue brick making

The gangue brick-making process is the same as the clay brick-making process, which mainly includes preparing, shaping, drying, and baking raw materials. In the brick-making process, coal gangue can use the heat dissipation characteristics to make adobe- and briquette-free bricks.

- Coal gangue production of cement

Cement production from coal gangue requires “two grinding and one burning”; that is, the coal gangue is combined with a certain proportion of limestone, ground into fine materials, and burned into partially melted clinker with calcium silicate as the main body to obtain components. Grind the cement into fine powder after adding the appropriate amount of gypsum and mixing materials. This production process can save the amount of coal used in clinker calcination and reduce the consumption of clinker coal; it can improve the burnability of cement raw materials, is beneficial to the stability of the thermal system, and improves the quality of cement clinker. - Chemical product production

Aluminum compounds are extracted from coal gangue. After the coal gangue is mixed with limestone or soda lime, it is calcined at a high temperature to activate the alumina in the coal gangue and then leached with acid or alkali solution, washed, and dried to obtain aluminum compounds.

To sum up, we can understand that coal gangue powder has many uses. Therefore, it is essential to choose good gangue grinding equipment.

How to Remove Pyrite From Coal Gangue?

Removing pyrite from coal gangue typically involves specific methods to separate or reduce the pyrite content. Pyrite is a sulfide mineral containing iron and sulfur, and its removal is essential to enhance the quality of coal gangue. Here are some standard methods:

- Froth Flotation

Froth flotation is a widely used method for separating minerals based on their differences in surface properties.

In the case of coal gangue containing pyrite, appropriate flotation agents are added to create a froth that selectively captures pyrite particles, separating them from the gangue. - Physical Separation

Techniques such as gravity separation, magnetic separation, or electrostatic separation can be employed to separate pyrite from coal gangue physically.

These methods exploit the differences in density, magnetic properties, or electrical conductivity between pyrite and gangue minerals.

- Oxidation

Oxidizing agents like hydrogen peroxide or oxygen can convert pyrite into water-soluble compounds.

It makes pyrite more amenable to removal through leaching or other separation processes. - Acid Leaching

Acid leaching involves treating coal gangue with acids, which can dissolve or react with pyrite, removing it.

The choice of acid depends on the specific requirements and characteristics of the gangue. - Microbial Leaching

Some microorganisms can catalyze the dissolution of pyrite. This method is known as microbial leaching or bioleaching.

Bioleaching is an environmentally friendly approach but may require longer processing times. - Combination of Methods

Depending on the complexity of the gangue and the concentration of pyrite, a combination of different methods may be employed to achieve efficient removal.