Blogs Related Mining Equipment, Projects & Process Plants

Copper Ore Production Process

The production process of copper ore processing mainly includes crushing, ore grinding, flotation, purification, and drying.The copper ore that needs to be processed must first go through the crushing process. The vibrating feeder is fed through the silo, and the vibrating feeder is evenly sent to the jaw type for primary crushing,

How an Overflow Ball Mill Works?

Ball mill is a common crushing equipment widely used in mining, metallurgy, chemical industry, and other fields. An overflow ball mill is a basic form of ball mill, its main feature is that the feeding port and the discharging port are set at both ends of the grinding cylinder. The

Ore Particle Size Affects Flotation Index

For flotation concentrators, ore particle size (also known as grinding fineness) is an important factor affecting the final flotation index. Practice has shown that the appropriate particle size generally means that more than 80% of the useful minerals have been dissociated from the monomers. If the ore particles are too

The Beneficiation Processes of Copper-cobalt Ore

Cobalt is a silver-gray metal with the element symbol Co and atomic number 27. It belongs to Group VIII. It has a melting point of 1495°C and a boiling point of 2870°C. It is ductile and ferromagnetic. It is relatively stable in air at room temperature. When it is higher

Exploring Types and Features of Rotary Dryers

The rotary dryer has a wide application range, convenient operation, and a high operation rate. It is widely used in the cement industry to dry raw materials and fuels such as clay, slag, crushed stone, and coal. During drying, the hot air or hot flue gas transfers heat to the

Discover the Different Types of Cone Crusher

Cone crusher plays an essential role in the mining industry. It is a crushing machine suitable for raw materials in metallurgy, construction, road construction, chemical, and silicate industries. So it’s commonly used in mining, smelting, building materials, roads, railways, water conservancy, the chemical industry, and many other sectors. The cone crusher

Wheel Bucket Sand Washer Troubleshooting

The bucket wheel sand washer is a high-efficiency sand washing equipment used with the sand making machine. It can remove impurities covering the surface of sand and gravel. At the same time, destroy the water vapor layer covering the sand to play a role in cleaning. It is more common

Tantalum and Niobium Ore Beneficiation Process in Africa

Tantalum and niobium are non-ferrous metals with a high melting point, possess many high-quality properties, and are key raw materials for industrialization. Tantalum and niobium have a high melting point (2996°C for tantalum and 2468°C for niobium), good ductility, very low vapor pressure, strong corrosion resistance, and high heat transfer

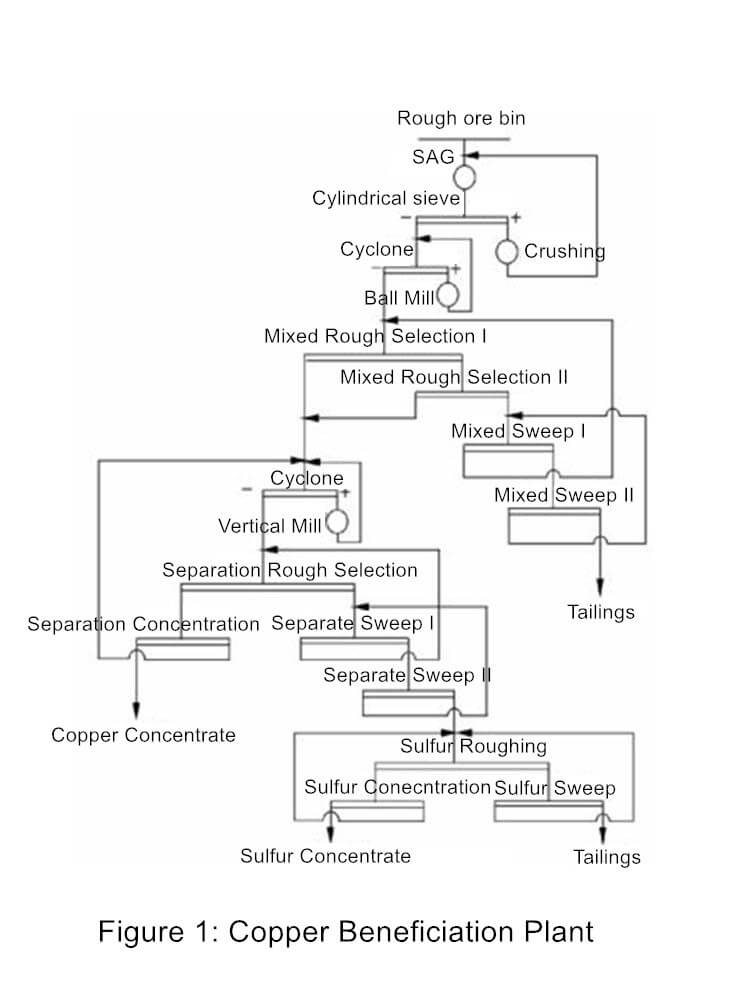

Copper and Associated Gold Ore Recovery Rate Improvement

Chalcopyrite is an important copper ore. Since chalcopyrite is often associated with pyrite, improving the separation effect of copper and sulfur is an important technical issue in copper sulfide flotation. Follow we will introduce a copper ore dressing plant that has greatly improved the recovery rate of associated gold mines while increasing the recovery

Mineral Dressing Process: Separation Operation

With the rapid development of modern industry, human demand for natural mineral resources is increasing daily. The mineral dressing process refers to the process of continuous processing of ore. The mineral dressing is a constant production process consisting of ongoing operations. Mineral raw materials enter the sorting operation after crushing