Blogs Related Mining Equipment, Projects & Process Plants

Gold Ore Flotation Considerations and Influencing Factors

Gold ore flotation is a complex process that involves various considerations and is influenced by several factors. In this article, we will discuss the important considerations and factors that can affect the efficiency and success of gold ore flotation. Precautions for Gold Ore Flotation Gold ore flotation extracts gold particles

Rare Earth Ore: From Mining to Application

Welcome to an exciting journey into the realm of rare earth ores! In this blog, we will explore rare earth ore, its distinctive features, wide-ranging applications, global distribution, the intricate process of mining these valuable elements, and the beneficiation of rare earth. What is Rare Earth Ore? Rare earth ore,

Coal Preparation Method: Wet & Dry Selection

There are many kinds of coal preparation methods, which can be summarized into two categories: wet and dry coal preparation. The coal preparation process is carried out in water, heavy liquid, or suspension, called wet coal preparation. The coal preparation process is carried out in the air, called dry coal

Crushers: Types, Maintainance, Selection

Crushers are mechanical devices or machines that reduce the size of large solid materials into smaller fragments, particles, or powders. They play a crucial role in various industries such as mining, construction, recycling, and manufacturing. Crushers are designed to efficiently break down different materials, including rocks, ores, minerals, concrete, and

Beach Placers Introduction & Mining

A beach placer, also known as a placer deposit, is a type of mineral deposit that forms on the beach or along the shoreline. It is a concentration of valuable or heavy minerals transported and deposited by natural processes such as water currents, waves, and tides. The beach placer is

Fluorite Types and Beneficiation Methods

Fluorite, also known as fluorspar, is a calcium fluoride (CaF2) mineral. It is commonly found in various colors, including purple, green, blue, yellow, and colorless. Fluorite is known for its cubic crystal structure and is prized for its beauty and various industrial uses. Fluorite has numerous applications. It is used

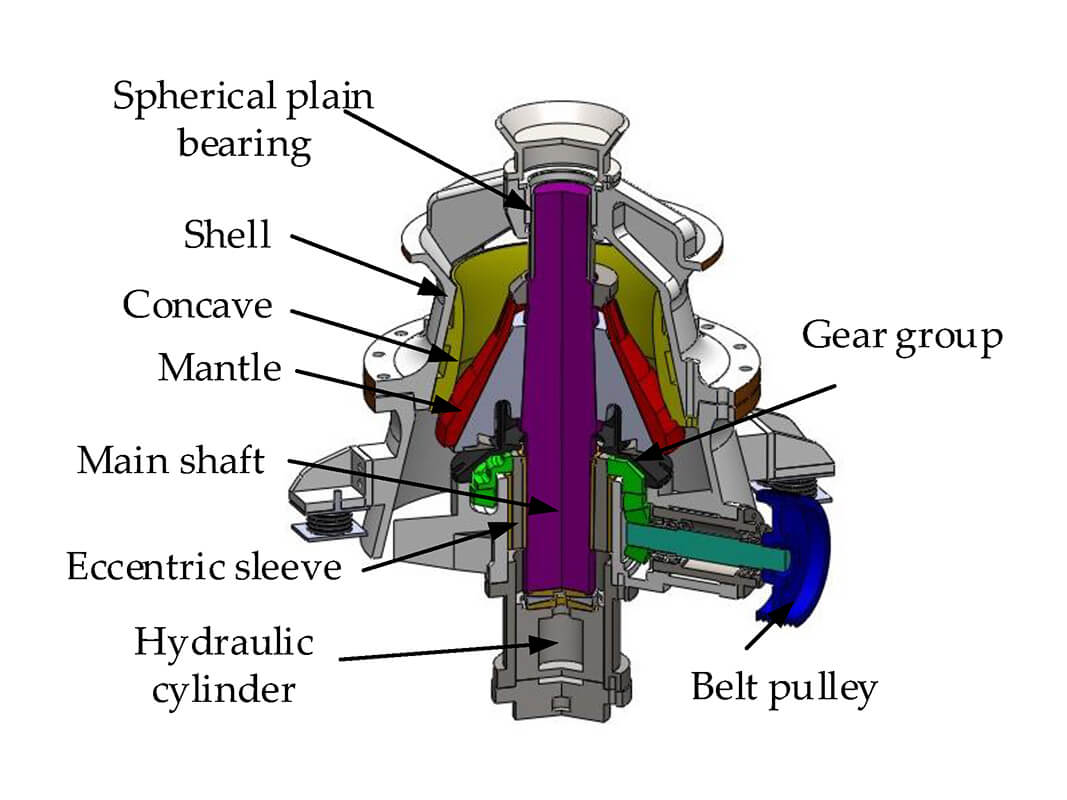

Cone Crusher Wear Parts & Replacement

A cone crusher is a crushing equipment commonly used in the mining and aggregate industries. It’s known for its efficiency in crushing hard and abrasive materials. The cone crushers are widely used in quarrying, mining, and construction. It is used to crush materials by squeezing them between a mantle and

Q&A on Mineral Processing Knowledge

As a newcomer to the beneficiation industry, there will be a lot of knowledge to learn. Beneficiation is a significant science, including mineral processing methods, technologies, equipment, and beneficiation solutions. In this process, we will encounter common questions and answers about beneficiation. As a professional mining equipment manufacturer and mineral

Copper Ore Processing And Equipment

Process Flow of Disseminated Copper Ore The flotation copper separation process of disseminated copper ore is relatively simple. The raw ore is crushed and ground by a crusher and a ball mill. The final grinding fineness is about 200 meshes, and then the flotation machine performs a rough selection, and

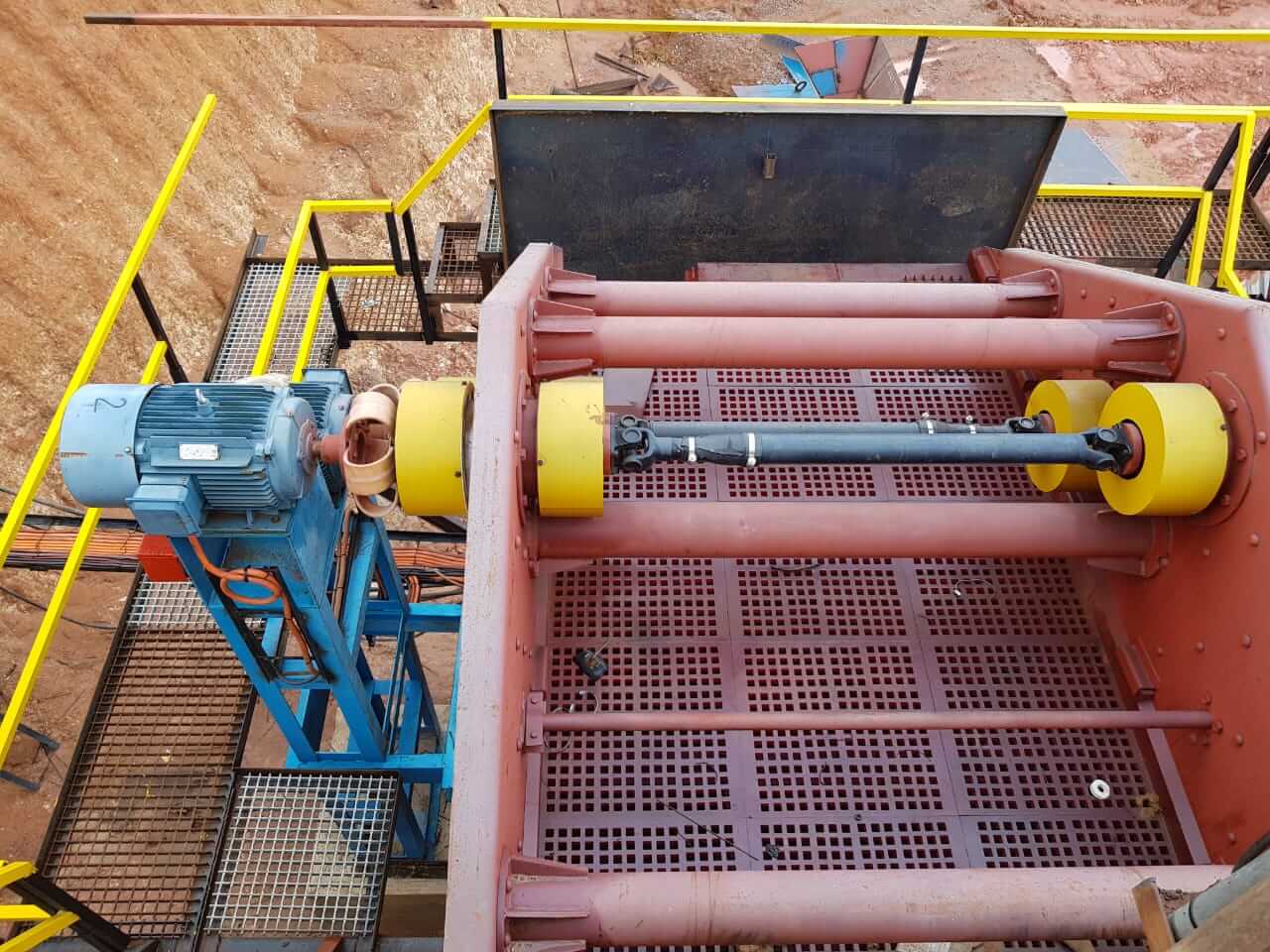

Common Faults and Solutions of Mineral Processing Equipment

The mineral processing equipment commonly used in mineral processing plants includes crushing, grinding, screening, magnetic separation, flotation, etc. Following we will analyze and discuss the wearing parts of screening, magnetic separation and flotation equipment, and the leading causes of wear. Screening Equipment Screening equipment is the equipment used for material classification. Many types of