Blogs Related Mining Equipment, Projects & Process Plants

Sand Making Machines: Types, Failures, and Lifespan Enhancement

Sand making machine is a kind of equipment used to crush large stones or ores into sand, which is widely used in the production process of construction, mining, water conservancy, transportation, and other industries. It is mainly used for manufacturing artificial sand (mechanism sand) and for processing many kinds of

Metal Recovering From Wast-to-energy Plants

With the acceleration of urbanization, the increase in the amount of waste has become a common concern. In order to solve the problem of waste disposal, thermal waste-to-energy plants have come into being. However, waste-to-energy plants generate metal wastes in the process of waste treatment, and these metal wastes, if not handled

Energy-saving Ball Mill VS Cement Ball Mill

Ball mill is one of the most commonly used grinding equipment in the market. This equipment has a very good grinding effect on crushed materials. There are many different types, among which energy-saving ball mills and cement ball mills are the most frequently used. Energy-saving Ball Mill An energy-saving ball

11 Uses of Mine Waste Rock and Tailings

Mine waste is the economically unproductive rock or minerals removed directly from the ore extraction. This waste is usually generated during the ore extraction because it does not contain enough valuable minerals. Tailings are the fine-grained waste materials that remain after the ore has been through the beneficiation or smelting

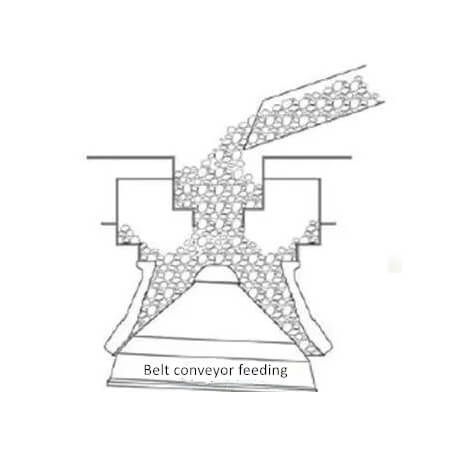

Cone Crusher Blockage: Causes and Prevention

Cone crusher is an important secondary crushing equipment and plays an important role in the production line. In the production process, due to improper operation or equipment abnormality, cone crusher will cause blockage during the production process, forcing the equipment to stop, wasting a lot of time cleaning up the

What is Lead Ore and How to Crush?

Lead is a metal element with the symbol Pb and the atomic number 82. It is the non-radioactive element with the largest atomic weight. It is a metal with a higher density than most materials. The lead blocks we see are usually gray-brown. The original color of lead is bluish-white,

Flotation Columns VS Flotation Machines

Flotation is a technique widely used in mineral processing to separate valuable minerals from gangue or waste materials. The process involves introducing air bubbles into a slurry consisting of finely ground ore and water. The air bubbles attach to the hydrophobic particles and bring them to the surface for easy collection. There are

Tin Ore Dressing: Gravity, Flotation And Magnetic Separation

Tin is a metal widely used in metallurgy, chemical industry, electronics, machinery, and other fields. Its beneficiation process is crucial for the effective utilization of tin ore resources. Tin ore dressing usually involves a variety of methods, among which gravity separation, flotation and magnetic separation are the most commonly used.

Gold Tailings Impacts and How to Recycle Them

Tailings in mining are the waste materials left over after the extraction of valuable minerals or metals from ore. When ore is processed to extract the desired mineral, a substantial amount of the original material remains as a finely ground slurry of waste. Tailings are the leftover materials from the

Four Key Issues About Ore Grindability

The ball mill is an important part of the mineral processing equipment. It is widely used in the production line configuration as an important part of mineral processing after grinding. The grindability of ore is a specific indicator to measure the resistance of ore to external forces, which measures the