The flotation process generally includes roughing, multiple selections, and multiple sweeps. The process is more complicated, and the effect is easily affected by many factors. The following three factors are mainly introduced: flotation time, pulp concentration, and pulp pH value.

The Flotation Time Effect on Flotation Process

The flotation time is the residence time of the pulp in the flotation machine. The operation flotation time is the residence time of the pulp in the flotation cell of the operation. And the sum of the flotation time of the roughing operation and each sweep operation is the total flotation time of the process.

The effect of flotation time on the process

The most suitable flotation time for various ores is determined through experimental research.

The following conditions can result in shorter flotation times:

- The minerals have good floatability.

- The content of floating minerals is low.

- The ore-feeding particle size of flotation is appropriate.

- The pulp concentration is small.

- The drug has a strong effect.

- The more strongly inflated the flotation machine is.

Contrary to the above, it requires a longer flotation time.

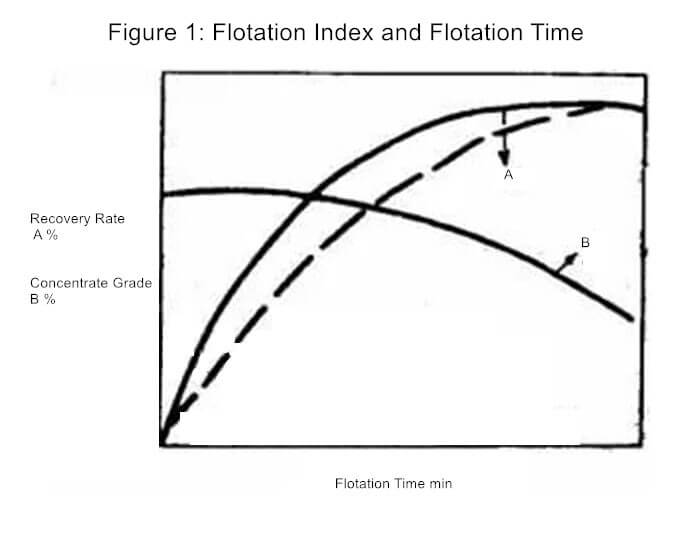

Figure 1 shows the relationship between flotation time and flotation index.

Increasing the flotation time can increase the recovery rate but decrease the concentrate grade. The recovery rate increased rapidly at the beginning and gradually decreased with increasing flotation time until a fixed value.

In flotation practice, the length of flotation time is often used to judge flotation’s speed (rate). Obviously, the shorter the flotation time required to achieve the specified or required recovery, the faster the flotation speed. When designing a flotation plant, the number of flotation machines of the specified type is often determined by the flotation time required to meet the design indicators. In the flotation plant that has been produced, the actual flotation time is usually calculated through the process inspection to judge whether the flotation operation is reasonable and whether the number of flotation machines is sufficient.

Increasing the slurry concentration can shorten the flotation time in actual production under the premise of the same amount of processed ore. When the number of processed ore increases, increasing the slurry concentration can alleviate the shortage of flotation time.

Increasing the number of roughing, sweeping, or flotation cells within a specific range can increase flotation time and help improve recovery. Increasing the number of selections or flotation cells can increase the concentration selection time, enhancing the concentrate grade and reducing the recovery rate.

Influence of pulp concentration on flotation effect

Flotation concentration is an essential technical parameter in the operation of flotation technology. Pulp concentration influences technical and economic indicators such as concentrate grade, recovery rate, chemical and water, and electricity consumption.

1. Influence on flotation time

After the production scale of the flotation plant is determined, under a certain slurry concentration, the flow rate of the slurry entering the flotation operation is certain. When the pulp concentration increases or decreases, the pulp flow also decreases, and the pulp’s residence time in the flotation machine will be prolonged or shortened, as shown in the figure. The change in flotation time directly affects the recovery rate and the quality of concentrate products.

2. Influence on the volume concentration of the agent

Generally, the dosage of a certain chemical in a flotation plant is calculated based on the grams of chemical required to separate 1 ton of raw ore (g/ton). If the dosage of the agent in this unit is unchanged, then the volume concentration of the agent in the pulp will change with the pulp concentration, as shown in the figure. In the process of flotation, for a specific mineral, the dosage of the agent in the calculation of the volume concentration of the agent is often “insufficient” or “excessive,” which causes unfavorable conditions and affects the flotation index.

3. Influence on the aeration of the pulp

The effect of pulp concentration on aeration volume is shown in curve 1 in the above figure. If the pulp concentration is too large or too small, the aeration of the pulp will be affected. Generally speaking, a larger aeration volume can improve the flotation machine’s production capacity and obtain a better flotation index.

How to choose a more suitable pulp concentration?

It determined the size of the slurry concentration according to the ore properties and flotation conditions. The general principle is that when the ore’s specific gravity is large, and the ore particle size is relatively coarse, it should use a larger flotation concentration for roughing and sweeping operations. On the contrary, if the specific gravity of the ore is small and the particle size is finer, it is better to use a lower concentration in the selection operation or the separation operation of the mixed concentrate. Flotation concentration in production practice: 25-45% for roughing, 10-20% for selection, and 20-30% for sweeping.

The effect of pulp pH on flotation

In the process of gold ore flotation, the impact of pH value on flotation is multi-faceted and is an essential factor affecting the flotation index. It can explain the effect of pH value on mineral flotation from the following three aspects:

- The effect of pH on the surface hydrophilicity and electrical properties of the ore particle. In the pulp with higher pH value, due to the large number of OH- ions in the pulp, a large amount of OH- is adsorbed on the surface of the mineral particles, which will increase the surface hydrophilicity of mineral particles and hinder the adsorption of collector anions. The pH value also affects the electrical properties of the surface of the ore particles. The size of the pH value directly affects the zeta potential of the surface of the ore particles. Especially for the flotation of some oxidized ores, due to the different pH values, the flotation reagents used are also different.

- pH value affects the effectiveness of flotation reagents. Most flotation reagents act on the surface of minerals in the form of ions. The reagents can only interact with the surface of minerals after dissociating into ions.

- Various minerals have a suitable pH value. Various minerals have a critical pH value of floatable and non-floatable under different chemical conditions. Therefore, the pH value of pulp often directly or indirectly affects the floatability of minerals. However, the critical pH value changes with the flotation conditions. If using different collectors or changing their concentration, the critical pH value of the minerals will also change.