Blogs Related Mining Equipment, Projects & Process Plants

Differential & Bulk Flotation: Which is Right for Your Mine?

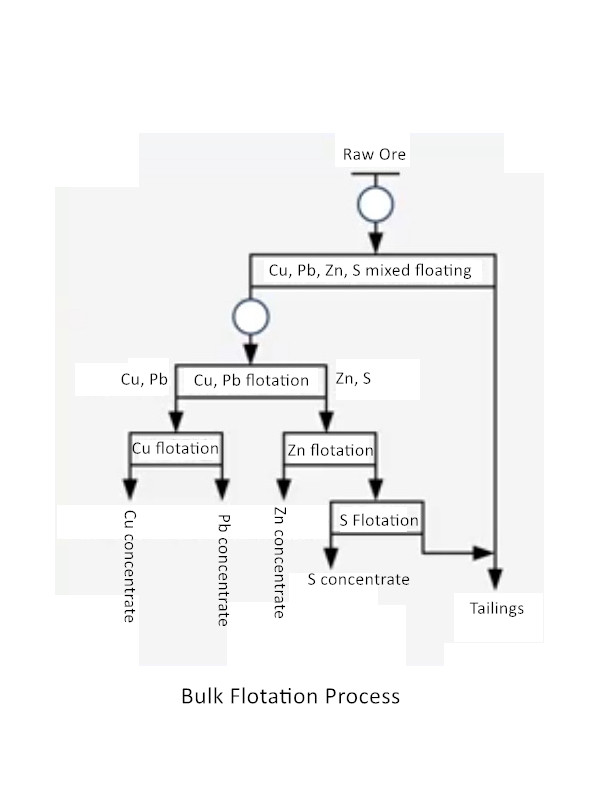

Want to improve your mining operation’s efficiency and profitability? Understanding the differences between differential and bulk flotation is key. Choosing the right method impacts your bottom line. Differential flotation separates valuable minerals and waste from each other. Bulk flotation recovers multiple valuable minerals together. This key difference impacts your processing

How to Select The Gold Mining Equipment?

Are you struggling to find the right equipment for gold mining? With so many options available, it can be overwhelming. I’ve been there, too. Let me guide you through the process so you can make an informed decision. Gold mining equipment selection depends on the ore type, processing method, and plant

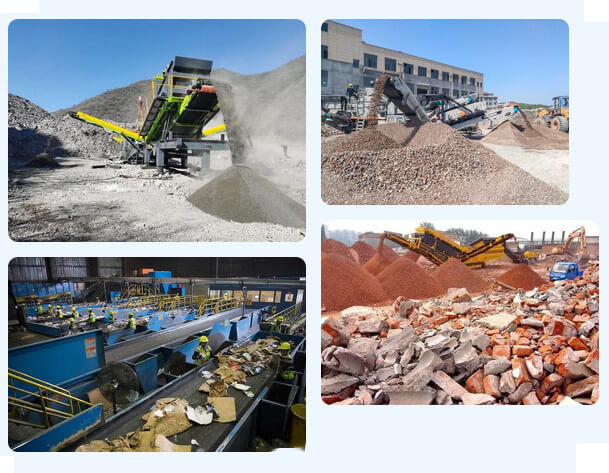

Uncovering The Current Situation And Treatment of Construction Waste

Recycling construction waste resources is an effective way to transform construction waste into useful products. Most can be reused as renewable resources after being crushed, screened, removed, and dusted by professional equipment. Construction waste refers to the slag, abandoned soil, materials, silt, and other wastes generated during the construction, laying,

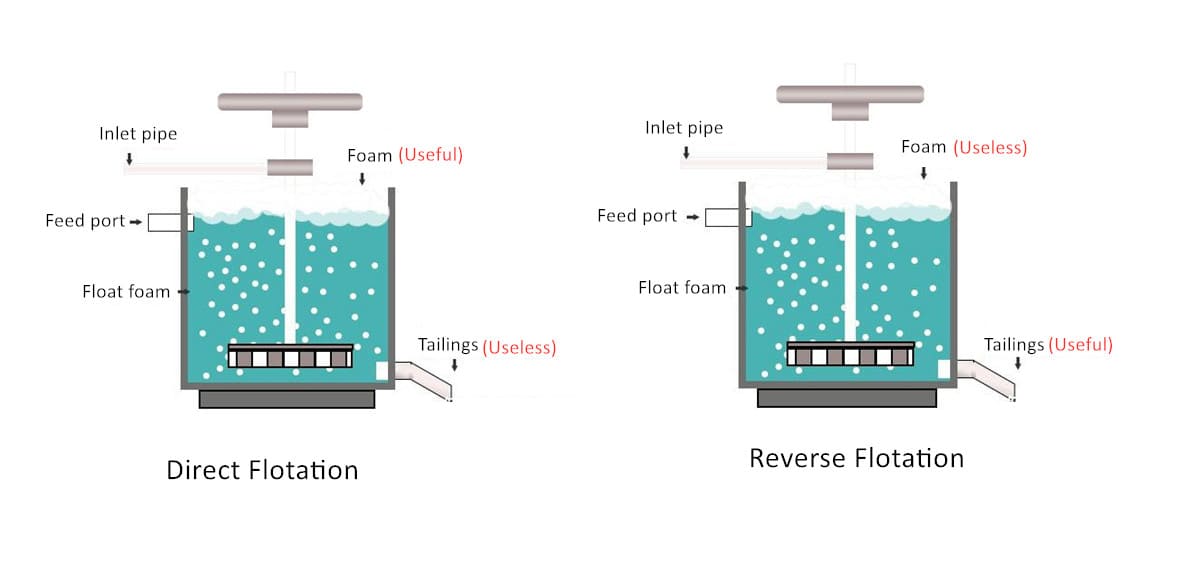

Direct Flotation & Reverse Flotation Contrast

As a key technology in the field of mineral processing, flotation technology is widely used in ore processing. Through crushing and grinding, different materials in the ore are separated into monomer particles. After reaching the appropriate particle size, flotation technology is used to extract valuable minerals. In this process, direct

4 “What” Help You Know Plate High Gradient Magnetic Separator

The flat plate high gradient magnetic separator is a new type of equipment manufactured by JXSC Mineral. The design and development of the whole machine integrate physics, fluid dynamics, and magnetic structure mechanics. It has extremely high magnetic induction strength, and the maximum magnetic field reaches 15000GS. The invention of this

The Use of Ore Washing Machine in Clay Minerals

Clay minerals are a class of aqueous silicate or aluminosilicate minerals, whose chemical composition, in addition to water generally contains a large amount of SiO2 and Al2O3, some also contain a certain amount of Fe2O3, MgO, and a small amount of K2O, Na2O, CaO and so on. Clay ore minerals

Multi-layer Shaking Table With High Site Utilization

As a classic gravity mineral separation equipment, the shaking table is widely used to separate fine-grained minerals. It is based on the working principle of the difference in density of mineral particles and realizes the effective separation of minerals through the lateral water flow and the reciprocating motion of the

Understanding Iron Ore: Varieties & Characteristics

Iron ore is an essential raw material for iron and steel production enterprises. Natural ore (iron ore) is gradually separated iron through crushing, grinding, magnetic separation, flotation, gravity separation, and other process. Iron ore is a collection of minerals containing iron monomers or iron compounds that can be utilized economically.

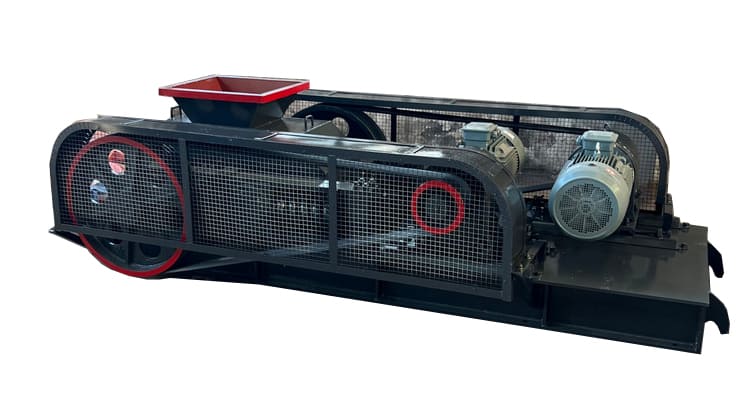

Factors Governing Roll Crusher Capacity

As a kind of crushing equipment, Roll Crusher is widely used in medium and fine crushing operations of high hardness materials in the chemical industry, metallurgy, building materials, refractory materials, and other industrial sectors, which is characterized by low noise, less dust, stable performance, and easy maintenance. Its capacity, i.e.

Germanium Ore Recycling: Restoring The Luster of Rare Resources

Germanium stone is a collective name for a group of natural ores that contain the element germanium. Germanium is a chemical element, but also a rare metal. The surface of germanium is silver-gray crystals, with properties similar to tin room temperature crystal Germanium is brittle, with obvious non-metallic properties; The